Tractor with 130 specifications

Until now, many businesses and individuals are working with equipment produced in Soviet times. This category includes the T-130 tractor, the technical characteristics of which allow it to compete even with some modern models.

General overview of the bulldozer

Tractor T-130 belongs to the class of caterpillar self-propelled machines. It is used for many types of work in various industries. A bulldozer was produced at the Chelyabinsk Tractor Plant, which can be called the leader in the production of special machinery at that time. This model came off the assembly line from 1969 to 1988. For the basis was taken tractor T-100, which by that time is already outdated.

There are two main modifications: the basic version of the tractor and the swamp. The latter was distinguished by wider caterpillars and slightly rearranged layout. This allowed the use of this model in wetlands and peat bogs. Even after thirty years the tractor continues to be used. It has two main characteristics: maintainability and high operational life.

In later years, other variants of equipment were produced on the basis of the T-130 tractor. For example, pipelayers, rippers and others. Direct follower was the T-170, which installed a power unit with a capacity of 174 liters. from. The tractor cabin can accommodate several people. It is protected from mechanical influences and is equipped with additional noise insulation, ventilation, insulation, cooling system. In addition, the driver's seat is adjustable. The only negative is a strong vibration.

As already mentioned above, the tractor is repairable, it can be found with any spare parts. The T-130 is a model that can easily be repaired in the event of a breakdown. Details of this tractor are produced by a plant in Chelyabinsk, where the machine itself was manufactured. On sale there are not only individual parts, you can purchase the whole units and blocks needed for repair.

Application area

The T-130 bulldozer is quite a versatile machine. It is used to perform complex and time-consuming processes in various fields of activity. The main area of application of the tractor can be considered agriculture. It is used for plowing at great depth, cultivation, plowing of unprocessed plots, harrowing. You can also transport cargo there.

The tractor can be aggregated with additional elements. This expands its scope, allowing the use of a bulldozer in construction, forestry, land improvement, industry and other industries. For this purpose, dozers, dumps, winches and other aggregates are connected to the bulldozer.

Model Device

The construction of the T-130 tractor is practically the same as its analogs. Differences mainly affect the technical stuffing and power of machinery. Two stamped spar, which connect with the rear axle, form the chassis. The device is a semi-rigid suspension with a spring placed transversely. Additional attachments are raised hydraulically. The hinged system itself consists of two parts: the rear and the front. It can be rigid or pendulum.

Dimensions of the tractor

The T-130 bulldozer belongs to the sixth traction class. Its total weight is 14.3 tons.

Dimensions are as follows:

- The length is 5.19 m;

- The width is 2.48 m;

- The height is 3.09 m.

With such dimensions, the gauge is 1.88 m. The ground clearance is 0.41 m.

Specifications

Initially, the D-130 engine was installed on the bulldozer. In 1981, it was replaced by a new power unit D-160 with a capacity of 140 horsepower. The turbocharger provides a balancing mechanism. Nozzles are installed without pins. This is achieved through the bronze bushes, put on the heads of the cylinders. They look like levers with two shoulders on top. If the engine is idle for a long time, the fuel supply to the second and third cylinders is cut off. This is another feature of the fuel pump, which can significantly save on fuel consumption.

Which engine does the T-130 have? The unit is considered diesel. But for start-up, a mixture of gasoline (A-76 or A-72) with engine oil in a ratio of 20: 1 is required. The voltage of the engine with an electric starter is 24 V. The fuel consumption is on average 244 g / kW. It is worth noting that the tank is installed at 290 liters. For oil there is a capacity of 32 liters. The cooling system of the engine works by means of a fluid with forced circulation. The heat carrier is driven by a centrifugal pump.

Transmission

The manual gearbox is typical for the T-130. The tractor's specifications are supplemented by twelve gears, of which eight are the front and four rear. The transmission works on the basis of moving gears. This ensures smooth speed switching.

The transmission of the model includes in its design the following elements:

- gear box four-shaft;

- the onboard reducer has two stages;

- on-board clutches dry with several disks;

- clutch;

- rear axle.

A distinctive feature of the bulldozer from modern models is the availability of a rotary mechanism. It allows the caterpillars to give different speeds. But this mechanism has its own minus. It consists in the rapid wear of many elements. The engine with the transmission is connected by means of a friction clutch.

Electrical equipment

Unified autocad nodes are also characteristic for the electronic system of the T-130 tractor. The electronic equipment of the bulldozer is controlled by means of a single-wire twelve-volt circuit. It includes an energy source, a rectifier, a generator. These elements are necessary for starting the engine, heating the cabin, ventilation, the operation of the glass cleaners, the sound signal. There are also additional electronic fuses. They serve to protect the system from short circuits.

Tractor control

To control the tractor T-130 there is a system of pedals and levers. There are several ways to rotate:

- By means of hydraulic switching of speeds on a transmission during movement.

- Due to the special rotation clutch. On the rear axle, two couplings connected to the shafts are installed at once. When the clutch is turned on, the torque transmission to it stops. Due to this, one caterpillar slows down. Thus, the tractor turns.

- It is possible to deploy the tractor in one place. This is done using a coupling. Around it there is a band brake. If it is sharply tightened, the rotation of the caterpillar will stop immediately.

The T-130 bulldozer is a reliable and maintainable version of the technology for various fields of activity. Despite the termination of its release, which happened thirty years ago, it has enjoyed a well-deserved popularity so far.

INTRODUCTION

1. The main technical characteristics of the tractor T-130

1.1. Basic Parts

1.2. Controls and starting of its engine

2. The fundamentals of operation and design of the T-130 tractor engine

2.1. The general device of the engine

2.2. Engine operation

3. The system of starting the tractor T-130

4. The chassis of the tractor T-130

4.1. Double disc clutch

CONCLUSION

LIST OF USED LITERATURE

INTRODUCTION

A tractor is a self-propelled machine used as an energy source for the movement and activation of agricultural and other machinery, as well as for towing trailers. The tractor engine can drive the working parts of stationary agricultural machines through the power take-off shaft (PTO) or with a pulley tool.

By appointment, agricultural tractors are divided into three groups: general purpose, universal-tilled and special.

According to the design of the chassis, tractors are caterpillar and wheeled.

The crawler tractor has a large supporting surface and therefore slightly crumples and compacts the soil. Such a tractor with high permeability can develop a large pulling force.

A wheeled tractor is more versatile than a caterpillar and can be used in both field and transport operations, but it has worse grip on the soil.

According to the type of skeleton, tractors are divided into frame frames, the skeleton of which is represented by a riveted or welded frame; semi-frame, the skeleton of which is formed by two short longitudinal beams, pinned or welded to the hull of the rear axle; Frameless, the skeleton of which consists of interconnected bodies of separate mechanisms.

According to the nominal tractive effort, tractors are divided into ten classes, differing in design. Ten traction classes make up the type of agricultural tractors.

In this paper, the technical device and general characteristics of the internal operation of the T-130 tractor manufactured by the Chelyabinsk Tractor Plant will be considered.

The goal work is to study the general characteristics of the device tractor T-130.

The T-130 tractor belongs to general-purpose tractors. General purpose tractors are used for the performance of basic agricultural works common in the cultivation of crops (plowing, discing, continuous cultivation, harrowing, sowing, harvesting). These tractors are distinguished by low ground clearance and increased engine power.

Tractor class T-130M - 6. Tractors of this class are effectively used in fields of large area when performing energy-intensive agricultural and meliorative work.

1. The main technical characteristics of the tractor T-130

1.1. Basic Parts

Tractors are complex self-propelled machines, which consist of separate mechanisms and assembly units.

The main parts of the tractor. Their location is shown in Fig. Regardless of the design features, tractors consist of an engine 1 , transmission 4 , undercarriage 6 , the management mechanism 2 , a worker 5 and auxiliary 3 equipment.

Engine is a source of mechanical energy.

Transmission is a set of mechanisms that transmit torque * from the engine's crankshaft to the driving wheels and change the torque and speed of the drive wheels in terms of value and direction. The transmission includes a clutch, a coupling, a gearbox (gearbox) and a rear axle.

Clutch it is necessary for a short-term detachment of the motor shaft from the gearbox when changing gears and for smoothly connecting them when starting.

The coupler, including the elastic elements, allows the coupling shafts and gearboxes to be connected with a slight misalignment.

Fig.1. The location of the main parts on the tractor T-130:1 - the engine;

2 - control mechanism;

3 - auxiliary equipment;

4 - transmission;

5 - working equipment;

6 - propeller.

* Torque is the moment of force, under the action of which the body rotates. It is defined as the product of power on the shoulder of its application.

Rear axle . By means of its mechanisms, the torque increases and the rotation of the shafts to the driving wheels is transmitted at right angles. Most tractors have brakes in the rear axle.

In the wheeled tractor, unlike the caterpillar, a differential is included in the transmission, which ensures different speeds of rotation of the driving wheels when turning and moving over uneven terrain, when the left and right wheels run a different length.

Chassis a tractor is required for movement. The rotational movement of the wheels (or caterpillars) upon their adhesion to the soil surface is converted into the tractor's forward motion.

The control mechanism serves to change the direction of the tractor.

Working Equipment The tractor is used to use engine power when performing various agricultural works. The working equipment includes a power take-off shaft (PTO), a trailing device, a hinged system, a drive pulley.

Auxiliary equipment of tractor - a cabin with a sub-seat, heating and ventilation, a hood, lighting, alarms, etc.

The general technical characteristics of the T-130 tractor are presented in Table. 1.

Rated operating power engine, kW (hp) |

117,7 (160) |

| Rotational speed, rpm: | |

| Crankshaft at rated power | 1250 |

| .. YOURSELF | 1000 |

| Diameter of the cylinder, mm | 145 |

| Piston stroke, mm | 205 |

| Specific fuel consumption at rated operating power, g / kW * h (g / hp-h) | 244,3 (180) |

| Applied fuel for: | |

| ..the main motor | diesel |

| Starting motor | mixture of gasoline of automobile A-72 or A-76 with engine oil of diesel engine in the ratio of 20: 1 by weight |

| Fuel tank capacity, l | 290 |

| Track, mm | 1880 |

| Longitudinal base, mm | 2478 |

| Ground clearance, mm | 415 |

| Width of shoes, mm | 500 |

| Specific pressure on the soil with the rear attachment mechanism, MPa (kgf / cm2) | 0,05 (0,5) |

| Overall dimensions, mm | 5193 X 2475 X 3085 |

| Weight, kg | 14320 |

1.2. Controls and starting of its engine

On modern agricultural tractors equipped with diesel engines with starting from an auxiliary engine, the controls of the tractor and both engines are located in the cab (by the example of the T-130 tractor) (Fig. 2).

To prepare the starting engine for operation and control its operation, use: a handle 1 control of the crane of the gas tank, handle 5 control of the air damper of the carburetor, the switch 11 ignition magneto, switch 15 starter, lever 27 control of the clutch of the reducer of the starting device and the inclusion of the starting gear.

When preparing the main engine, a lever is used to work 8 decompression mechanism (decompressor), lever 20 fuel flow control, a "mass" switch, a fuel cock and a manual fuel pump (located outside the cabin).

To control the tractor in the cabin the following levers and pedals are located.

Levers 9 and 10 control mechanisms of the rotation of the crawler tractor. To rotate the tractor along a large radius arc, the corresponding lever is gradually pulled back.

Lever arm 19 turning on the torque magnifier (UKM). When you move it to yourself, the torque magnifier turns on. In the on position, the lever can be locked by a latch.

Lever arm 20 fuel management. When moving it down, the fuel supply increases. To switch off the fuel supply, the lever is lifted to the extreme position.

Pedal 21 master clutch control. If you press the pedal, the clutch will turn off.

Lever arm 23 PTO shaft control. To turn on the PTO, the lever is moved back. When the front position of the PTO lever is off.

Pedals 25 and 26 right and left brakes. For a steep turn of the tractor, push only the brake pedal, from which the control lever is pulled.

Lever arm 28 change gear. The gears can only be switched when the main clutch is completely switched off.

Levers 30, 29 and 31 control of the main and external cylinders of mounted implements located respectively behind, from the right and left sides of the tractor. Depending on the position of each lever, the following types of movements and the status of the attachments are possible: upward movement - "Lifting", down to the first fixed position - neutral position, down to the second fixed position - "Lowering", down to the stop of the fuel - "Floating position" .

Control and measuring devices and signal devices. These include a tachometer 2 ; pointer 4 pressure ammeter 6; pointer 12 water temperature in the cooling system; check lamp 13 , signaling a reduced oil pressure in the lubrication system; pointer 14 oil pressure in the lubricating system UKM; pointer 16 oil pressure in the engine lubrication system; check lamp 17 , signaling the inclusion of the battery on the "mass"; pushbutton switch 18 sound signal.

Fig. 2 Controls of the tractor T-130

1- crank handle for the petrol tank;

2 - tachometer;

3-switch of electric motors of heating and ventilation of the cabin;

4 - the fuel pressure indicator;

5 - the handle of management of an air заслонкой the carburettor;

6 - ammeter;

7 - the switch of forward headlights;

8 - the lever of management of the decompression mechanism;

9 - the lever of management of a brake of the left planetary mechanism of turn of a tractor;

10 - the lever of management of a brake of the right planetary mechanism

11-button ignition magneto;

12 - the index of temperature of a cooling liquid in the engine;

13 - the control lamp signaling about the lowered pressure of oil in the lubricating system of the engine;

14 - the index of pressure of oil in lubricating system UKM;

15 - starter motor starter switch;

16 - the index of pressure of oil in engine lubrication system;

17- the control lamp signaling inclusion of the storage battery on "weight"; 18-button switch for sound signal;

19- the lever of inclusion УКМ;

20 - the lever of management of giving of fuel (a regulator);

21- the pedal for controlling the main clutch;

22 - the tractor driver's seat;

23 - the control lever of PTO;

24 - sector of fixation of a pedal of the right stopping brake in the braked condition;

25 - a pedal of the right stopping brake;

26 - a pedal of the left stopping brake;

27 - the lever of management of coupling of a reducer of the starting device and a starting gear wheel;

28 - the lever of a gear change;

29, 30 and 31 - the control levers, respectively, the right outrigger, rear main and left remote cylinder of the hinged system.

Preparing the engine for starting. Before starting a cold engine, it is necessary to carry out the maintenance operations (ETO); remove the air from the power system (if the engine has not worked for a long time) and fill it with fuel, using a manual pump of the pumping pump for this; make sure that the levers 28, 29, 30 and 31 are in neutral position, and the lever 23 switched off; close the radiator cover, and also remove the side cover of the engine hood.

Start the engine. To facilitate scrolling of the crankshaft, the decompressor is turned on by putting the lever 8 in the lowest position. If the engine is not working for a long time, turn the crankshaft by two to three turns. Cranes of fuel tanks of the main and starting engines are opened. The latter is opened by turning the handle against the clockwise direction. Lever arm 20 set to the highest position corresponding to the switched off fuel supply. Introduce the starting gear to engage with the crown of the flywheel of the diesel engine by turning the lever 27 up to the end up, and then transfer it downwards, thereby having switched off the clutch of the reducer of the starting device. Cover the air flap of the carburetor of the starting engine by pulling the handle 5 to myself. Plug the battery into the electrical circuit by pressing the large button of the "ground" switch located on the front wall of the cabin until it is locked.

Then turn on the starter by turning the switch lever 15 starter clockwise. .

As soon as the starting engine starts to work, it is necessary to fully open the air damper of the carburettor by placing the handle 5 in the front position, and let the engine idle for no more than 2 minutes. Continuous operation of the starting engine does not result in overheating.

After warming up the starting engine, the clutch of the reducer of the starting device is smoothly switched on. Warm up the main engine with the decompressor on for 1 ... 2 minutes before creating pressure in the engine oil line and turn off the decompressor. If, at the same time, the speed of the starting motor shaft starts to decrease, you must turn on the decompressor, after warming up the diesel engine, again turn it off. With the stable operation of the starting engine, a full fuel supply is included. After the start of stable operation of the diesel, it is necessary to switch off the clutch of the gearbox, to muffle the starting motor by pressing the switch button 11 ignition magneto, and set the fuel supply lever to the middle position. Continuous operation of the starting motor for more than 15 minutes is not permitted.

If the starter or battery is faulty, the starting motor can be started manually. To do this, remove the flywheel housing of the starting engine together with the starter, lay the starter assembly in one of the cutouts on the flywheel of the starting engine, lay 1.5 ... 2 turns of the cord into the groove in the direction of rotation indicated by the arrow on the flywheel, and a quick jerk by the handle cord start the engine. Hold the cord while turning the handwheel only by the handle. Do not wind the cord around your arm, as the crankshaft can turn in the opposite direction during start-up and tighten the hand between the cord and the flywheel. If after three or four attempts the engine does not start, it is necessary to check the ignition and the flow of fuel into the carburettor; troubleshoot and repeat all operations. After the start-up of the diesel, the crane of the starting engine is closed, the bonnet hood is replaced, and the tool is removed.

After start-up, the diesel must be heated, gradually increasing its speed from medium to maximum within 2 ... 3 minutes. Thus it is necessary to listen carefully to the engine and to check up indications of control devices. The engine should work evenly, without interruptions and knocking. The emission of exhaust gases must be smokeless. It is possible to load the engine only after its warming up to a coolant temperature of at least 50 ° C. The radiator curtain must be completely lowered (open) at a water temperature of 75 ° C.

The oil pressure in the lubricating system of the heated engine should be 0.3 ... 0.5 MPa. If the manometer does not show oil pressure when the engine is running, stop the engine immediately and repair the faults. In the warm season, it is possible to start the engine without turning on the decompressor. In this case, the crankshaft must be scrolled without turning on the fuel supply until the oil pressure in the engine's lubrication system appears, and then turn on the fuel supply.

In conditions of low ambient temperatures, pre-start heaters are used to facilitate start-up, or hot water is poured into the cooling system, and hot oil is poured into the oil pan. In case of severe frosts, water, heated to 60 ... 70 ° С, is first passed through the cooling system with an open water filler, and then, when the drain cock is closed, water is poured into it with a temperature of 90 ... 95 ° С. To facilitate the start-up, it is necessary to fill the cylinder of the starting engine with a crane in the head 2 ... 3 cm 3 of a mixture of gasoline and oil, and also pull off the button of the enrichment device on the diesel fuel pump.

Stop the diesel engine. To do this, turn off the fuel supply. But before stopping, it must run for 3 ... 5 minutes at idle speed with medium and low speeds of the crankshaft (to evenly lower the temperature of the oil and water). Do not stop the diesel by closing the fuel cock. This can cause the air to suck in the power system, which will make it difficult to start the engine. After stopping the diesel, you need to turn off the battery by pressing the small side button of the "ground" switch. Indicator lamp 17 at the same time it must go out.

2. The fundamentals of operation and design of the T-130 tractor engine

2.1. The general device of the engine

For normal operation of the engine, a combustible mixture must be supplied to the cylinders in a certain proportion (for carburetor engines) or measured fuel portions at a specific time under high pressure (for diesel engines). To reduce the work costs to overcome friction, heat removal, prevention of scuffing and rapid wear, the friction parts are lubricated with oil. In order to create a normal thermal regime in the cylinders, the engine must be cooled. Due to the high compression ratio, it is not possible to manually start the diesel. It is equipped with a starting device.

Diesels differ from carburetor engines in that a combustible mixture is formed inside the cylinder and spontaneously ignites from the temperature of the compressed air. They are used as the main engines on modern heavy-duty tractors.

Engines installed on tractors include similar mechanisms and systems.

The device of diesel engines. All diesels installed on the tractor consist of the following mechanisms and systems.

crank mechanism converts the rectilinear motion of the pistons into a rotational motion of the crankshaft.

Gas distribution mechanism controls the operation of the valves, which allows in certain positions of the piston to let in air into the cylinders, compress it to a certain pressure and remove therefrom the exhaust gases.

Supply system ensures the supply of measured fuel portions at a certain point in the sprayed state into the cylinders of the engine.

Lubrication system It is necessary for continuous supply of oil to the rubbing parts and for removing heat from them.

Cooling system protects the walls of the combustion chamber from overheating and maintains in the cylinders a normal thermal regime.

Starting system It is necessary for cranking the crankshaft during start-up.

The location of the components of the various systems of the tractor diesel engine is shown in Fig.

a is a right view; b - left view;

1-oil dipstick;

2 pins for installing the piston of the first cylinder at the time of fuel supply;

3 - oil filler neck;

4 - the oil filter;

5 - coarse fuel filter;

6 - an exhaust collector;

7 - air cleaner;

8 - the fan;

9 - generator;

10 - hydraulic steering pump;

11 - front engine support;

12 - the pump of manual pumping of fuel;

13 - the fuel pump;

14 - the compressor;

15 - injector;

16 - fine fuel filter;

17 - the lever of an air заслонки an emergency stop of the engine;

18 - the valve of release of air from fuel system;

19 - electric starter;

20-starting motor;

21 - reducer of the starting device.

2.2. Engine operation

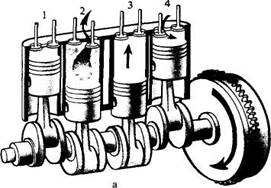

The T-130 tractor is equipped with a four-cylinder, four-stroke D-160 diesel engine with a turbocharger.

The duty cycle of four-stroke engines is made in two revolutions of the crankshaft. During this time, the crankshaft receives an effort from the piston only with one half-turn corresponding to the working stroke of the piston. Three other half-turns continue by inertia, and the crankshaft with the help of a flywheel moves the piston with all the auxiliary strokes (discharge, intake and compression). As a result, the crankshaft of a single-cylinder engine rotates unevenly: during the working stroke, it is accelerated, and with auxiliary cycles it is slow. In addition, a single-cylinder engine usually has low power and increased vibration. Therefore, modern tractors and cars are equipped with multi-cylinder engines.

In order for the multi-cylinder engine to work evenly, the expansion bars must follow through equal angles of rotation of the crankshaft (i.e., at regular intervals). To determine this angle, the cycle time, expressed in degrees of rotation of the crankshaft, is divided by the number of cylinders. For example, in a four-cylinder four stroke engine, the expansion stroke (working stroke) occurs 180 ° (720: 4) with respect to the previous one, i.e., half the revolution of the crankshaft. Other strokes of this motor alternate also through 180 °. Therefore, the crankpins of the crankshaft of the four-cylinder engines are located at an angle of 180 ° to each other, i.e., lie in the same plane. Crankpins of the first and fourth cylinders are directed in one direction, and the connecting rod necks of the second and third cylinders are in the opposite direction. This form of the crankshaft ensures a uniform alternation of working strokes and good balance of the engine, since all the pistons simultaneously come to the extreme position (two pistons down and two upwards - fig. 4).

Fig. 4. Scheme and operating procedure of the four-cylinder engine.

Crankshaft half-turn |

Angle of rotation of the crankshaft | Cylinders | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

| 0 ... 90 | Working |

The horses of the admission |

End of release |

End of compression |

End slave of the stroke |

||||

| 90 ... 180 | |||||||||

| Working stroke | |||||||||

| 180... 270 | Working |

||||||||

| 270... 360 | Working stroke |

||||||||

| 360... 450 | Working |

||||||||

| 450... 540 | Working stroke |

||||||||

Fourth |

540... 630 | Working stroke |

|||||||

| 630... 720 | Inlet | Release | Compression | Working stroke | |||||

The sequence of alternating cycles of the same name in cylinders is called the order of the engine. The order of operation of four-cylinder domestic tractor engines 1-3-4-2. This means that after the working stroke in the first cylinder, the next working stroke occurs in the third, then in the fourth and, finally, in the second cylinder.

3. The system of starting the tractor T-130

To start the internal combustion engine, it is necessary to crank the crankshaft at a rotational speed at which a good mixture formation is ensured, sufficient compression and ignition of the mixture. The minimum frequency of rotation of the crankshaft, at which a reliable start of the engine, is called starting. It depends on the type of engine and the starting conditions.

There are the following ways to start the engines: an electric starter, an auxiliary motor and manually with the help of a starting handle or cord, wound on the flywheel of the starting engine.

The T-130 tractor has a starting system from a carburetor starting motor with an electric starter (Fig. 5).

Fig.5 Starting motor:

Fig.5 Starting motor:

1 - an exhaust pipe;

2 - a water drainage branch pipe;

3 - spark spark plug;

4 - cock for purging the cylinder and filling fuel;

5 - a head of the cylinder;

6 - the cylinder;

7 - the carburettor;

8 - a cap of an air cleaner (plastic);

9 - filtering element (polyurethane foam);

10 - the regulator;

11- magneto;

12 - картер;

13 - condensate drain plug;

14 - a gear wheel of a cranked shaft;

15 - connecting rod;

16 - a flywheel;

17 - a cranked shaft;

18 - the piston.

Start-up electric starter is the most common way to start many tractor engines. The starter is easy to operate, it greatly facilitates the work of the driver, but requires qualified maintenance, has a limited supply of energy, which reduces the number of possible attempts to start the engine.

4. The chassis of the tractor T-130

The tractor chassis includes a transmission, a chassis and a control mechanism.

The transmission consists of units that transmit the torque from the engine to the driving wheels and change this torque and wheel speed both by numerical value and direction. The main transmission units are schematically shown in Fig. 6

The transmission consists of units that transmit the torque from the engine to the driving wheels and change this torque and wheel speed both by numerical value and direction. The main transmission units are schematically shown in Fig. 6 Fig. 6 Schematic of the components of the transmission:

1 - clutch;

2 - a gear box;

3 - gimbal transmission;

4 - the driving wheel (asterisk);

5 - semiaxes of driving wheels;

6 - the differential;

7- the main gear;

8 - final transmission;

9 - transfer case;

10 - caterpillar;

11 is an intermediate;

12 - turning mechanism.

Clutch allows you to briefly disconnect the engine and transmission when shifting gears and smoothly connect them when the tractor starts moving.

On modern tractors, friction clutch is used. The work of such a coupling is based on the use of frictional forces. As friction surfaces, discs made of a material with a high coefficient of friction are used. Depending on the transmitted torque, it is necessary to apply a different number of friction elements, so the clutch can be single-disk, dual-disk and multi-disk.

4.1. Double disc clutch

In the tractor T-130 double-disk clutch. The double-disk clutch, unlike a single-disk clutch, has two slave and two driving discs: intermediate 11 (Figure 7) and pressure 9 , installed alternately. On both sides of the intermediate disk there are four spring springs, which, when the clutch is disengaged, allow the disk to be positioned in the middle position between the flywheel and the pressure plate.

The hubs of the driven discs are placed on the splines of the clutch shaft. The front end of the shaft is supported by a ball bearing mounted in the flywheel bore, and the rear is connected by splines to the gearbox primary shaft and rests on its front bearing.

The driven clutch discs are sandwiched between the end faces of the flywheel and the drive disks with coil springs that are evenly spaced in the casing.

Push-up levers are attached to the casing with forks and nuts 7 . The outer ends of the levers are hingedly connected to the pressure plate, and the inner ends to the ring 6 . The clutch pedal is connected to the bearing through the fork 14 off, levers and traction.

When you press the pedal bearing 4 Move the ring forward with the inner ends of the push-up levers, and the outer ends of the levers 8 take the pressure plate back 9 . Under the action of expansion springs 10 the intermediate disk will depart from the flywheel and the pressure plate, rotation to the driven discs from the crankshaft will not be transmitted.

To quickly stop the driven discs and, therefore, the shaft serves as a brake. Block 16

The brake with riveted to it overlay at deenergizing of coupling is pressed to a shaft for what through a spring it is connected to the lever rigidly fixed on one axis together with a plug 14

.

To quickly stop the driven discs and, therefore, the shaft serves as a brake. Block 16

The brake with riveted to it overlay at deenergizing of coupling is pressed to a shaft for what through a spring it is connected to the lever rigidly fixed on one axis together with a plug 14

.

Fig. 6. Double-disk clutch (tractor T-130):

2-body;

3- spring;

4- squeeze out the bearing;

6 - squeeze ring;

7 - the adjusting nut;

8 - the push-button lever;

9-pressure plate;

10-expansion spring;

11 - intermediate disk;

12-slave drives;

13 - a groove of a flywheel;

14- the fork of the switch-off;

15- the adjusting nut the brake;

16- the brake shoe.

CONCLUSION

Tractor T-130 - caterpillar, general purpose, traction class 60 kN (6) in the unit with mounted and trailed machines is designed for earthmoving, plantation, meliorative, road, planning and agricultural work (plowing, sowing, continuous cultivation).

The manufacturer is the Chelyabinsk Tractor Plant. The beginning of series production - 1969 year.

The T-130 tractor has a four-cylinder, four-stroke D-160 diesel engine with a turbocharger, a combustion chamber in the bottom of the piston and a launch from a carburetor starting motor with an electric starter.

Transmission mechanical, multistage. It consists of a dry, permanently closed clutch with two driving and two driven discs, a four-shaft gearbox, a conical transmission, multi-plate dry side friction clutches and two-stage side reduction gears.

The brakes are tape, two-way, floating, with friction pads acting on the outer drums of the side friction clutches. The hydraulic clutch control system includes hydraulic servo mechanisms.

The frame of the T-130 bulldozer is made in the form of two spars welded to the body of the side friction clutches. Trolleys of caterpillars are welded, support rollers - five, supporting rollers - two. The tension wheel has a hydraulic tension mechanism. The caterpillar is made up of stamped links connected by fingers and bushings. Shoe special profile attached to the links.

Tractor T-130 is equipped with a separate-aggregate hydraulic system, front and rear attachments, pendulum or rigid trailing device. It is possible to install a power take-off shaft (PTO shaft).

Cab double, closed type, metal, with heat-soundproof seal.

For agriculture, the T-130 tractor, the T-130 bulldozer is equipped with a rear hitch.

On the order of the customer, a preheater heater for water and oil, an air heater, bursting couplings, ice rail spurs, asphalt shoes and a canopy, which can be installed in place of the cabin, can be supplied with the tractor.

LIST OF USED LITERATURE

1. Guskov VV, Velev NNTractors: A textbook for university students in the specialty "Cars and tractors" - M .: Mechanical Engineering, 1988. - 376 p.

2. Melnikov D.I. Tractors - 2 nd ed., Pererab. and additional. - Moscow: Academy, 1990. - 367 p.

3. Rodichev V.A. Tractors: A textbook for primary vocational education institutions. - 3rd ed., Pererab. and additional .- M .: ProfObrizdat, 2001. - 256 p.

4. Skotnikova V.A. Tractor and cars - M .: Agropromizdat, 1985. - 440 p.

5. AI Selivanov. Handbook on the repair of the machine-tractor park - M .: Publishing house of agricultural literature, magazines and posters, 1962. - 756 p.

6. Semenov VM, Vlasenko V.N. Tractor. - 3rd ed., Pererab. and additional. - Moscow: Agropromizdat, 1989. - 352 p.

7. Ustinov A.I. Agricultural machines: A textbook for primary vocational education. - 2 nd ed., Pererab. and additional. - Moscow: Publishing Center "Academy", 2000. - 264 p.

ChTZ: yesterday and today (T-130, T-170, T10, T11)

The history of the Chelyabinsk Tractor Plant dates back to 1933. ChTZ is the largest manufacturer of caterpillar industrial tractors, which is the base of bulldozer-ripping units, pipelayers and various road-building machinery (swampers, pile-drivers, cable laying machines, trench excavators, etc.). The main products of the plant are tractors and bulldozers of the most massive traction classes of 10-15 tons. These machines operate in a wide variety of industries and industries, as well as logging, communal and road maintenance. Tractors and bulldozers of ChTZ have a great resource and maintainability, which ensured the existence in operation of several generations of equipment under the brand ChTZ. These are bulldozers of the b-170 series, tractors t-170 and tractors t-130. Let's consider these models in more detail.

Tractor t 170 (t-170), bulldozer t 170 (t-170)

The first tractor t-170 came off the assembly line in the spring of 1988 and immediately proved itself only on the positive side, and a little later the bulldozer t-170 became the most popular special equipment. Technical characteristics of the t-170 are at a very high level, it is thanks to such technical indicators that it has gained its popularity.

You can buy a t-170 bulldozer with a choice of 80 different modifications and complete sets depending on the characteristics of the work and the climatic conditions in which it will be operated.

The t-170 bulldozer can be bought with 2 types of engines: D 160 and D 180. D 180 represents a newer and more modernized model of the D-160 engine, the power of this engine is 180 horsepower (160-160 hp). Torque reserve it also increased by 25%, compared to the engine of the older model. Using the engine D 180 on the tractor t-170 significantly increases its technical characteristics. In the development of new models of tractors, ChTZ adheres to the principle of continuity, which makes it possible to provide spare parts for the models of the ChTZ tractors removed from the main production. On your tractor it is always possible to install a part from a newer model of the tractor and improve the technical specifications of t 170. You can find out the prices for spare parts and repair of the t-170 from our managers.

The tractor is equipped with a frame cabin, which is mounted on a vibration-insulated platform, the cabin has a modern design. A large area of glazing enhances the operator's view.

| General indicators of the tractor t-170 | |

| Weight, constructional, kg | 15000 |

| Chassis Type | crawler |

| Traction class | 10 |

| Base, mm | 2517 |

| Track, mm | 1880 |

| Engine | |

| Engine brand | D180.111-1 (D-160.11) |

| engine's type | |

| Engine power, kW (hp) | 125 (170) |

| 218 (160) | |

| Refueling capacities | |

| Fuel tank, l | 300 |

| Cooling system, l | 60 |

| Engine lubrication system, l | 32 |

| 12 | |

| Hydraulic system, l | 100 |

| Overall dimensions of the tractor t-170 | |

| Length, mm | 4600 |

| Width, mm | 2480 |

| Height, mm | 3180 |

| 0,076 | |

Tractor T-130

T-130 is an industrial caterpillar tractor of general purpose with hydromechanical or mechanical transmission. According to technical characteristics, the t-130 belongs to the 6th traction class. The T-130 tractor was manufactured between 1969 and 1988. It is equipped with a four-cylinder, four-stroke diesel engine d-160 with a turbocharger.

The T-130 can be equipped with various attachments: bulldozer blade, traction winches and much more. Also, the T-130 is the base for many types of special equipment such as pile-ups, pipelayers, bar installations and for many others. Due to its constructive continuity, the T-130 - t-170 - t-10 - t-11 spare parts for this type of transport can be found in our time. For consumers, this means: manufacturing and repair of spare parts for machines discontinued (spare parts for T-130, T-170); the possibility of installing new units on old machines and replacing old tractors with new, more productive and comfortable ones; branded service for all ChTZ products. T-130, T-170, family T-10, T-11 have almost identical overall dimensions, close weight characteristics, that is, transportation conditions are the same.

| General indicators of the tractor t-130 | |

| Weight, constructional, kg | 12720 |

| Ground clearance, mm | 415 |

| Traction class | 10 |

| Base, mm | 2478 |

| Track, mm | 1880 |

| Engine | |

| Engine brand | D-130 |

| engine's type | Four-stroke diesel, turbocharged, multi-fuel |

| Engine power, hp | 140 |

| Specific fuel consumption, g / kW * h (g / l, h) | 244,3 (180) |

| Refueling capacities | |

| Fuel tank, l | 290 |

| Cooling system, l | 60 |

| Engine lubrication system, l | 32 |

| Onboard reducer (each), l | 12 |

| Hydraulic system, l | 100 |

| Overall dimensions of the tractor t-130 | |

| Length, mm | 5193 |

| Width, mm | 2475 |

| Height, mm | 3085 |

| Specific ground pressure, MPa | 0,05 |

Bulldozer б-170

Bulldozer b-170 was produced at the Chelyabinsk transport plant in the period from 1988 to 2002. B-170 is understood as a whole range of bulldozers and tractors of 10 traction class produced by the ChTZ plant. The bulldozer's base is the industrial tractor t-170, so the technical characteristics of the b-170 are also at a high level. For 14 years, during which the bulldozer was produced, he proved himself only on the positive side. This bulldozer has high maintainability, it is able to work even in the harshest places of our country. There are practically no analogues in the domestic market for special machinery. The competition is made only by bulldozers of foreign production, but the price of bulldozer b-170 is much lower than that of foreign analogs.

The repairability of the bulldozer is due to the fact that the B-170 was developed as a result of the modernization of the T-130 tractor, increasing the engine's power to 170, and then to 180 hp, and simultaneously reducing the specific fuel consumption. The gear ratio of the on-board reducer of the bulldozer B-170 was raised 1.5 times by increasing the maximum tractive effort and significantly unloading the power transmission, the resource of the T-170 bulldozer increased to 8 before the first major overhaul, and then to 10,000 moto-hours, 170 corresponded to all world standards.

Technical characteristics of bulldozer B-170

| Overall dimensions with working equipment | ||

| Length with hemispherical blade and rigid trailing device, mm | 5673 | |

| Length with hemispherical blade and ripper, mm | 6867 | |

| Operating weight | ||

| With hemispherical blade, hydraulic ram, three-tooth ripper, with full fuel and oil filling, kg | 19570 | |

| Ripper | ||

| A type | Multi-tooth | Single-tooth |

| Maximum number of teeth | 3 | 1 |

| Number of tooth positions (vertical) | 3 | 3 |

| Maximum depth, mm | 650 | |

| Angle of loosening, degree: | ||

| - with a short tip | 45 | 45 |

| - with a long tip | 30 | 30 |

| Weight, kg | 2245 | 1555 |

| Bulldozer equipment | ||

| Type of blade | Hemispherical | Straight |

| Changing the cutting angle and the transverse skew angle of the blade | Screw and hydraulic braces | |

| The volume of the drawing prism, m3 | 4,75 | 4,28 |

| Blade width, m | 3,31 | 3,42 |

| Height at cutting angle 55 deg | 1,31 | 1,31 |

| Maximum lift, m | 1,02 | 1,02 |

| Maximum depth, m | 0,44 | 0,44 |

| Maximum skew, m | 0.63 (10 deg.) | 0.63 (10 deg.) |

| Adjusting the cutting angle, deg | 10 | 10 |

| Weight, kg | 2313 | 2240 |

| Overall dimensions of the tractor T-170 | ||

| Length, mm | 4210 | |

| Width, mm | 2480 | |

| Height, mm | 3250 | |

| Track, mm | 1880 | |

| Base, mm | 2880 | |

Instead of a hemispherical blade on the bulldozer B-170, a straight, instead of a multi-toothed ripper, can be installed: a toothless or rigid trailing device, which greatly extends the use of the bulldozer.

In contrast to past years, ChTZ produces not only tractors, but also basic attachments for them: direct, rotary, hemispherical and spherical dumps; single and three-edged rippers; pipelaying equipment; winches. Modern analogues of dozers DZ-110 (DZ 110), DZ-171 (DZ 171) are B-10 (B10, B10), B-11 (B11, B11); Pipelayers TG-124, TO-1224 - pipelayers TR-12 (TR12, TR 12), TR-20 (TR20, TR 20) of the Chelyabinsk Tractor Plant and TBG-20 of the Berezovsky Mechanical Repair Plant. ChTZ continues the production of various spare parts for the T-170, including the chassis components, including the T-170 caterpillar.

Tractor T-130 is a general purpose caterpillar. The tractor was produced in 1969 at the Chelyabinsk Tractor Plant. To date, the release of this model is discontinued.

Tractor T-130: specifications

Tractor T-130 was used separately or in the unit with other devices. After the modification, the production of the T-130 model ceased. In place of its predecessor came the tractor T-170, more powerful, but less durable. The result of modernization was the cessation of production of both models of tractors.

Engine and fuel system

Tractor T-130 is equipped with four-stroke four-cylinder power unit D-160. The engine power is 160 hp. and 117.7 kW. The crankshaft rotates at a speed of 1250 rpm. The power take-off shaft produces 1000 rpm.

The diesel engine is equipped with a turbine and a pre-start system using an electric starter. The combustion chamber is located in the bottom of the piston. The cylinder diameter is 145 mm, the stroke of the piston is 205 mm. The main engine runs on diesel fuel. Pre-trigger mechanism uses a mixture of gasoline A-71 or A-76 with engine oil. The fuel tank holds 290 liters of fuel.

Transmission and chassis

Transmission tractor T-130 - multi-stage mechanical. Clutch clutch dry with four disks: two driving and two driven. Transmission - four-shaft with one conical transmission and 8 workers.

For safe braking in any direction, belt brakes are used in the tractor. The design of the brake system is floating with friction pads. On-board clutches are additionally controlled by hydraulic servomechanisms. It was the friction that became the most short-lived part of the tractor.

Like many caterpillar tractors of Soviet type, the T-130 is placed on a welded frame of two spars. The frame is welded to the side clutches, which ensures maximum reliability. The five-caterpillar caterpillar system is welded, two rollers are used for support.

The tensioning wheel uses a hydraulic tensioning mechanism for easy operation. The caterpillar is assembled from stamped links, which, in turn, are connected by fingers and bushings.

Hydraulic system

The hydraulic system of the tractor is separate and modular. The machine uses rear and front attachment. In addition, the tractor is equipped with a rigid or pendulum mechanism for the trailer. It is optionally possible to install a power take-off shaft. Agricultural modifications were produced with a rear hinged system.

Cabin

The closed-type tractor cabin is made of a single-piece metal sheet. Inside there are two seats. Only heat insulation seal is available from comfort systems. At the request of the buyer instead of the cockpit could be installed awning.

At the request of the customer for the tractor T-130 were also delivered:

- preheater oil and water heater;

- air heater;

- spurs for movement during icing;

- bursting couplings;

- asphalt shoes.

Tractor T-130: application

Tractor T-130 has traction class 6. In the unit with or without attachments and trailers, the machine can be used for:

- agricultural work (plowing of soils, reclamation, processing before sowing, etc.);

- communal and road works (in the unit with pipelayer or pile digging);

- construction works (in the aggregate with a bulldozer);

- needs of forestry.

Tractors T-130, even after the modification did not meet modern requirements. The design and systems of these tracked vehicles were considered obsolete, and the chassis of the tractor proved to be unreliable. While the "contemporaries" of the T-130 began to use hydromechanical transmission and more comfortable operator cabs, the Soviet tractor continued to operate on the systems of the 30s. This approach of the manufacturer has determined the future of the T-130.