How much does Belarus weigh

Limited Liability Company “RosTechImport” For many years, it has been a stable and reliable supplier of road, construction, utility equipment and domestic spare parts - imported production, as well as forgings made of carbon, alloyed, stainless steels and ductile non-ferrous metals, as well as stampings.

Competitivebenefits

The reputation of impeccable work over 10 years.

- sale of only original spare parts from manufacturers.

- a wide range and availability of spare parts in stock.

- Offices and warehouses of the company are located in one place, which contributes to convenient registration of transactions.

- the ability to order online through the company website.

- discounts for regular customers, the possibility of deferred payment.

- marketing services.

Our enterprise is an official Dealer of CJSC “Forging-Mechanical Plant Izhora-Metall” in the territory of the Russian Federation and the exclusive Distributor in the Republic of Belarus.

Specialistsbehindactivity activity:

- release press (weight up to 3.0 tons),

- Molotovy (weight from 0.2 kg to 2 tons) forgings from carbon, alloyed, stainless steels and ductile non-ferrous metals, as well as forgings (weight up to 30 kg), produced by hot forging.

The established traditions, qualified specialists, a wide fleet of equipment allows us to produce in the shortest possible time quality products for the energy and petrochemical engineering, the production of mining equipment, shipbuilding and the metallurgical industry.

There is a possibility of carrying out final heat treatment packages and batches of mechanical properties on batches.

Significantly accelerate the development of your order application, which will contain:

1. “Finishing” drawing details;2. Sketch of processing the part under the final heat treatment (taking into account the allowances for the sample and technological allowances for t / o);3. The number of parts;4. Contact phone performers.

Applications for the manufacture of forgings from 1 piece are considered.We accept orders for "re-forgings" of metal "customer".- sale of attachments to MTZ tractors and spare parts for them.- sale of technical literature (catalogs of parts and assembly units).

Dealer "Plant Euromash" Republic of Belarus.

Today, the enterprise “Plant Evromash” of the Republic of Belarus successfully works on the Belarusian and Russian market in the manufacture of specialized road and utility equipment for year-round road maintenance. In addition to the equipment for the Amkodor equipment, mounted working bodies are manufactured on the MTZ tractor.

Dealer "Mozyr Machine-Building Plant" RB

- The company produces a large range of engineering products, including for agriculture, forestry, for the needs of enterprises of the energy complex.

![]()

Tractor MTZ-82 "Belarus"

It is a modification of the tractor MTZ-80.

Operational power of the engine, kW (hp) 55.16 (75)

Rotation frequency, min - 1:

crankshaft 2200

PTO 545; 1010

Diameter of the cylinder, mm 110

Piston stroke, mm 125

Specific fuel consumption at operating power. g / kW - h (g / l. s.h) 251.6 (185)

Capacity of a fuel tank, l 130

Wheel track (adjustable), mm:

1400 rear… 2100

front 1350… 1800

Wheel tires:

front 11.2-20

rear 15.5R38

Tire pressure, MPa (kgf / cm3):

front 0.14 ... 0.25 (1.4 ... 2.5)

back 0.08 ... 0.14 (0.8 ... 1.4)

Longitudinal base 2450 mm

The smallest turning radius, m 4,3

Ground clearance, mm 470

Overall dimensions, mm 9330x 1970x2765

Weight (structural), kg 3370

It differs from the basic presence of the front drive axle and drive to it. Keeping all the qualities of the basic model, including versatility. It has an increased traction and coupling qualities. The front drive axle is a beam swinging in the eyes of the front beam and resting on the coil springs mounted in the final drive gearboxes. The main gear consists of bevel gears with a spiral tooth.

The front axle differential is tapered, self-locking. The final gears of the front axle are made in the form of bead gears with two pairs of bevel gears that simultaneously serve as hinges of equal angular velocities.

The transfer box, which transmits the torque from the gearbox to the front drive axle cardan drive, is a single-stage gear reducer with a roller clutch of free running. The transfer case is turned on and off during the front course of the tractor with the help of a overrunning clutch at the moment when the rear wheels slip exceeds the set value. The design of the transfer case provides for the possibility of forcibly switching on and off the front drive axle both in the rear and in the front course of the tractor, depending on the working conditions.

The cardan drive transmits torque from the transfer case to the front axle. It consists of two identical in design and length of the rear and front propeller shafts and intermediate support with a safety friction clutch.

The tractor is equipped similarly to the base model MTZ-80.

Tractor MTZ-82N "Belarus"

Wheeled, low clearance, rough terrain, is a modification of the tractor MTZ-82. Designed to work on mountain slopes with a steepness up to 0.28 rad (16 degrees) and a plain. It differs from the base model by a lower center of gravity, which is ensured by the installation of front and rear wheels of reduced diameter, overall height and increased longitudinal and transverse stability. The tractor is equipped with a D-240 engine (D-243).

Speed range without creeper (with creeper), km / h:

forward travel 1.72… 30.35 (0.51… 1.175)

the rear 3.62 ... 8.16 (0.242 ... 0.545)

Wheel track (adjustable), mm:

1400 rear… 2100

front 1500… 1900

The minimum turning radius of 4.3

Wheel tires:

front 11.2-16

rear 16.9R30

Angles of static stability, deg .:

transverse 50

lift 50

slope 61

Longitudinal base 2450 mm

Agrotechnical clearance, mm 610

Ground clearance 400 mm

Overall dimensions, mm 3850Х1970x2700

Weight (structural) with the main working equipment, kg 3550

The tractor is equipped with an inclinometer, showing the non-length of the longitudinal and transverse roll of the tractor, extended radiator neck, power steering, rear PTO. a separate-modular hydraulic mounted system with a hydraulic wheel of the driving wheels and a power (positional) regulator.

The tractor is equipped with a spacious sealed safe cabin, which is fixed to the chassis with the help of four rubber shock absorbers.

The cushion of the driver’s seat has suspensions that allow it to deviate relative to the longitudinal axis of the tractor in such a position that the driver stays upright when the tractor is on the slopes. The position of the cushion is fixed.

The design of the nodes and the technical characteristics are the same. as with the base model of the tractor MTZ-82.

Additional equipment to the tractor: drive pulley, side PTO; wheels with tires 15.5R38; 8.3-20; 9,5-42; creeper, PZHB-200B preheater.

Tractor MTZ-82R "Belarus"

The main units, units and systems are unified by tractors MTZ-80, MTZ-82, MTZ-80X.

Number of gears:

forward running 17

rear 1

Speed range, km / h 2.05 ... 27.3

Track, mm 1900

Longitudinal base 2450 mm

Minimum ground clearance, mm 660

Agrotechnical clearance, mm 715

Wading depth, m 1.0

Minimum turning radius in the middle of the front outer wheel track, m:

with braking 4.3

no braking 5.6

Tire type - wide-profile, low pressure with increased height of the cat-chains and slightly saturated tread pattern

Wheel tires:

front 16-20

rear 18.4R34

Overall dimensions, mm 4020x2370x3030

Weight (constructional), kg 4100

The MTZ-82R tractor has increased permeability compared to the MTZ-82 due to the increased agrotechnical clearance and special tires with increased height of the picker and a slightly saturated tread pattern, as well as a wider track. Increased ground clearance is provided by raising the tractor frame by installing a rear axle with an additional side drive, unified with the MTZ-80X tractor, and large-diameter tires compared to the base tractor.

The tractor allows to implement on a large scale progressive water tillage technology. ITS advantages are especially manifested in pre-sowing treatment and planning of rice checks filled with water, as well as on planning of steam checks for water. Serves tractor driver.

The tractor model MTZ-82 can be called the real pride of the post-Soviet industry. Their release was begun in the USSR, when in 1974 the first model left the assembly line.

It successfully continues today at the Minsk Tractor Plant, producing MTZ-82. So any domestic company can purchase proven equipment over the years, but manufactured in accordance with modern quality standards under the brand Belarus-82.

MTZ-82 is a deeply modernized MTZ-52, which was one of the most popular in the Soviet Union. MTZ-82 today does not lose its popularity in the CIS due to reliability, power and relatively compact size.

It should be remembered that the MTZ-82 design includes up to 70% of unified parts that can be used on other tractors, including the MTZ-50 and MTZ-52 models. All models MTZ -.

The MTZ-80/82 family of tractors was developed in the 70s of the last century, when the need arose to create universal special equipment competitive with foreign counterparts. This was the MTZ-82 model with an engine of up to 80 hp, which could be used to solve a whole range of tasks, from transporting felled trees in public utilities to cities to efficient plowing of fields. MTZ-82 belongs to the 1.4 class.

Belarusian 82 It is important to understand that constructively even modern Belarus-82 tractors represent deeply modernized MTZ-52 and they are distinguished mainly by modern exterior cladding, a functional and safe cabin, the equipment of a modern high power engine. Of course, we must not forget about the huge number of minor design changes that increase the overall strength and reliability of the structure.

Characteristics of the MTZ tractor to look at the video.

Today, the MTZ-82 tractor of various years of production can be used almost everywhere, they easily tolerate both northern frosts and the difficult road access of rural roads, driving through mud during snowmelt.

Most models have increased engine speed and good speed, so it can be used to transport heavily loaded trailers over long distances (compare with). On the Internet there is confirming this video.

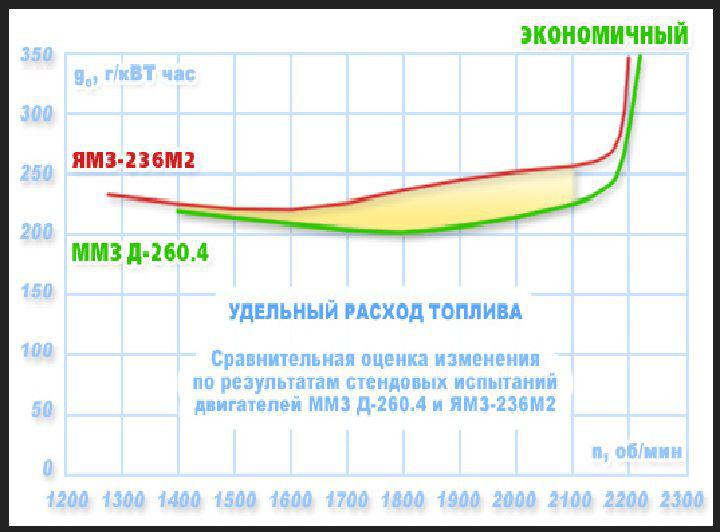

Fuel consumption

For each model, be it a modern Belarus-82 tractor or the Soviet MTZ-82, or, the accompanying documentation indicates the rate of fuel consumption on the basis of which it can be assumed real consumption, often slightly different from the standard.

It must be remembered that the actual fuel consumption depends largely on the following aspects:

- Climatic conditions.

- Season.

- Wear design.

- The quality of fuel and lubricants.

- Weight attachments.

- The complexity of the work performed.

Therefore, it is always necessary to apply a correction factor to the linear norms, which increases the base parameter.

The easiest way to measure fuel consumption is to fill the unit with a full tank and drive 100 kilometers on a tractor with a uniform load. Then you can determine exactly how much fuel was used both at the whole distance, and per kilometer, liters per hour.

Calculation formula for MTZ-82

Determination of fuel consumption To determine the exact amount of fuel consumption, you can use a formula that has been successfully tested by time and is actively used for MTZ-82 tractors.

Determination of fuel consumption To determine the exact amount of fuel consumption, you can use a formula that has been successfully tested by time and is actively used for MTZ-82 tractors. The formula includes the following basic parameters:

- Fuel consumption kg / hour, denoted as "P".

- The power of the tractor is a standard value of 0.7, the result of transferring the power of the MTZ-82 motor from kW to horsepower.

- Specific fuel consumption, denoted beech "R". For the model MTZ-82 is equal to 230 kW per hour.

- Engine power in horsepower is denoted as “N”. In the basic configuration MTZ-82 is usually equipped with an engine with a power of 75 horsepower, but today there are often options with motors with a capacity of 80 horsepower.

To accurately calculate the fuel consumption, it is necessary to calculate by the following formula: P = 0.7 * R * N.

The fuel consumption for the tractor in the basic configuration will be 12 kg per hour. Given that a liter of diesel fuel weighs about 840-875 grams, the flow rate is quite large.

However, during the survey, some tractor owners identified real fuel consumption from 7 to 10 liters per hour. Perhaps this is due to the fact that the engines in modern models (for example) are more economical.

Specifications

The MTZ-82 tractor was originally produced in several modifications, and to this day the units used in the CIS countries can differ greatly from each other, primarily in the method of starting the engine, appearance, attachments and type of transmission, which often gear ratios differ. Attachments MTZ 82 MTZ-82 can be equipped with different attachment points, have a different agrotechnical prospectus, have or not have a system for working on sharp slopes and a hydraulic control system. Often used a variety of rubber, selected for climatic conditions.

Attachments MTZ 82 MTZ-82 can be equipped with different attachment points, have a different agrotechnical prospectus, have or not have a system for working on sharp slopes and a hydraulic control system. Often used a variety of rubber, selected for climatic conditions.

But the semi-frame construction of various modifications of the MTZ-82 always has unified elements, such as:

- Front wheel guides.

- Rear wheels of large diameter.

- 75-80 hp diesel engine, located in front of the hull.

About tractor design t 70 -.

Dimensions and weight

MTZ-82 differs in relatively small dimensions., and has the following dimensions:

The standard agroscall for this model is 46.5 centimeters, for modifications with a wheel reduction gear, it is 65, for the MTZ-82N version, the ground clearance is 40 centimeters. The mass of the unit is 3,600 kilograms. It can be used everywhere, including for public services in cities, it should not harm the road surface, as well as.

MTZ hydraulic system According to standard MTZ-82 is completed with mechanical transmission with power steering and nine-speed gearbox with two ranges, equipped with a reduction gear.

MTZ hydraulic system According to standard MTZ-82 is completed with mechanical transmission with power steering and nine-speed gearbox with two ranges, equipped with a reduction gear. Initially, the model did not assume the presence of a hydraulically controlled gearbox, but on modern tractors it is often installed with the ability to switch under load. The hydraulic system allows you not to turn off the clutch when shifting gears within the four speed ranges.

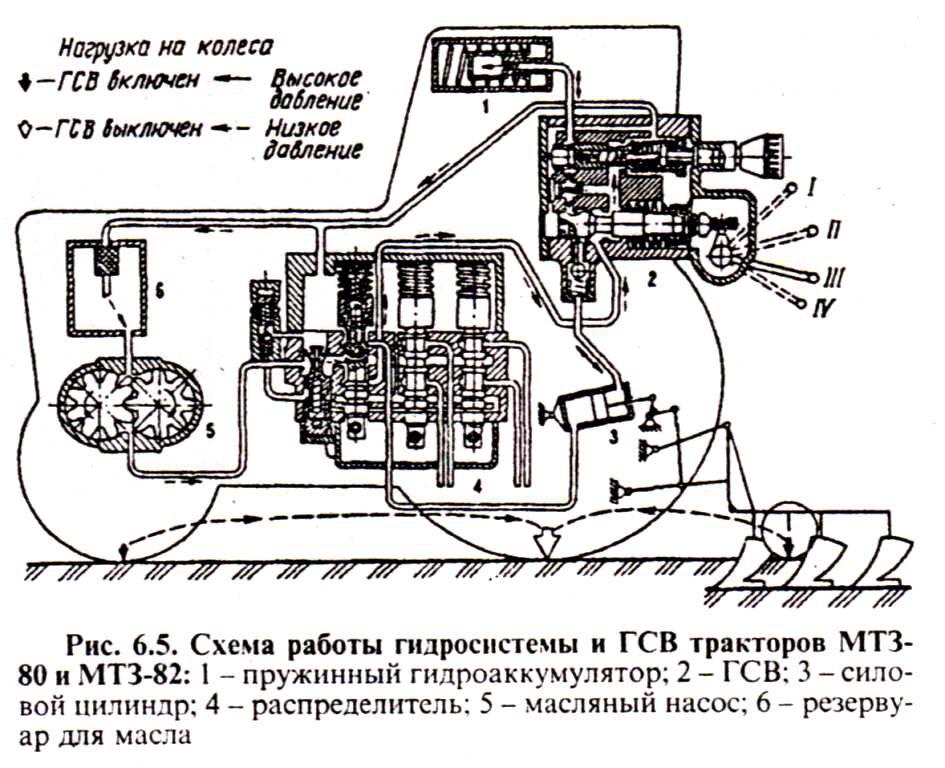

The separate-modular hydraulic system includes a gear pump, a hydraulic distributor and a hydraulic cylinder, with the help of which the attachments are controlled.

On the old tractors, most of which were produced in the USSR, the locking is controlled mechanically, with a pressure pedal located on the floor. Modern modifications are equipped with a hydraulic system - you can switch the mode using the switch located under the dashboard.

Watch the tractor test drive on video.

Engine

On the tractor MTZ-82 installed four-cylinder engine D-240 or D-243. This four-stroke unit produced at the Minsk Motor Plant and has a liquid cooled sub-split combustion chamber. The camera is located in the piston.

On some tractors, you can also find a preheater, which allows you to quickly and efficiently prepare the engine for operation in the winter. The heater ПЖБ-200Б is installed only if the ambient temperature during tractor operation is below 0 ° С, as soon as it reaches a value of 5 ° С in spring, the heater must be removed, dried and set aside until autumn.

The MTZ-82 engine has an average working volume of 5.75 liters. and power of 80 hp in modern models and 75 hp in earlier versions. The unit can be equipped with an electric starter or a 10 horsepower starting motor and a start blocking function in case the gear is already engaged.

Transmission

MTZ-82 is equipped with a modern transmission and has a stiff suspension of the rear wheels and a semi-rigid front, has a balance bridge. To secure the rear wheels, the terminal connections on the axles are used, thanks to which the tractor operator can smoothly change the track width, varying it from 140 to 210 cm. The track can be varied for the front wheels, but only in steps, each step is 10 cm.

Attachment Equipment

The MTZ-82 tractor can be equipped with the following attachments:

- Loader.

- Front loader.

- Blade.

- Snow dump

- Road brush.

- Ladle.

- Plow.

Thanks to the unified work elements on the MTZ-82, you can install a wide range of modern attachments for municipal and construction equipment.

On the video model MTZ-82 in work.

Maintenance

We can safely say that maintenance is a prerequisite for maintaining the tractor in good condition. It ensures proper operation and durability of components, high-quality operation of the unit.

It is important to remember that maintenance of MTZ-82 should be carried out systematically. The priority can be called maintenance in the spring and autumn, as well as preparing the equipment for work in particularly difficult conditions, for example, in desert areas, mountains, tundra.

It is advisable to adhere to the following scheduled maintenance schedule:

- Superficial - every 60 hours.

- Standard - every 240 hours.

- In-depth - every 960 hours.

It is important not only to perform basic operations, but also timely repair any damage found and prevent malfunctions.

Operating Instructions - Guide to Action

In order for the tractor to serve the owner as long as possible, and his work was uninterrupted, the following requirements must be observed when operating the unit:

- After the end of the shift, check for leaks of oil, fuel, and water.

- Add fuel regularly to the starting engine.

- Check the oil level only 20 minutes after the engine is running.

- Regularly check the water level in the radiator and drain the condensate from the pneumatic system.

When operating in difficult weather conditions - necessarily inspect the tractor according to individual requirements.

For example, clean the radiator net when working in a desert area.

Find out what to do so that a tow truck does not pick up your car.

Conclusion

The MTZ-82 tractor is a truly versatile unit designed to solve a whole range of tasks, especially in agricultural and communal work. Depending on the installed attachments, it can be used for soil preparation, transport operations, construction work, industry and manufacturing. The model has established itself as reliable and economical.

MTZ 82 was manufactured by the Minsk Tractor Plant, hence the second name of the car appeared - Belarus. Technical characteristics and low weight, refer the tractor to the 1.4 class of traction power.

The production line for the production of these tractors began work in 1978. For nearly 40 years, the technique can be found on the fields, construction sites and livestock farms. The car was produced by several tractor factories. During its existence, MTZ-82 Belarus has been modified several times. Consider this amazing machine in all its details.

Device engineering

Chassis

All main assemblies and mechanisms of the MTZ-82 Belarus are located on a steel half-frame reinforced with side members. The necessary stiffness provided intermediate support. Front axle - driven, equipped with wheels of a smaller radius.

Of the features we can note the telescopic sleeves, with the help of which the tractor can change the width of the track. The rear axle is the driving axle, on which, using terminal connections, wheels of a larger radius are mounted.

For the rear wheels, the possibility of doubling is provided, which increases the grip of the car with the road and significantly expands the capabilities of the tractor. For the front wheels, a suspension suspension is provided, the rear axle is fixed rigidly, by and large being a rear semi-frame.

Engine

The MTZ-82 tractor was first equipped with a low-power two-cylinder SK-12 diesel engine. The engine could produce about 12 horsepower, the type of cooling - air. Subsequently, Belarus MTZ-82, received as a power plant four-stroke diesel engines D-240 and D-243.

This is a four-cylinder engine with direct fuel injection. The working volume of the unit is 4.75 liters. The engine has a capacity of 81 horsepower, the speed of rotation of the crankshaft - 2,200 r / min. The diesel engine is distinguished by a vertical arrangement of cylinders and a semi-partitioned combustion chamber.

To start the power plant in some models, the PZHB-200 cold start system is installed. B. It is worth noting the combined engine lubrication scheme. One part of the working units is lubricated directly under pressure, the other by spraying. The engine is cooled liquid, for this purpose, oil or water type radiators are installed.

Transmission scheme

Transmission MTZ-82 Belarus speed, consists of a checkpoint, clutch and rear axle with differential, main and final gears. On the front axle, which is also included in the transmission scheme, install gearboxes and differential with the possibility of self-locking.

Gearbox, which is installed on the tractor, manual, there is a reduction gearbox, doubling the number of gears. A total of 18 front and 4 rear speeds are provided. The speed range for the forward course varies from 1.8 to 33.4 km / h. Reversing the tractor can move at a speed of 4 to 9 km / h. For the transfer of power to the attachment, a two-speed independent power take-off shaft is responsible.

Differential rear axle - conical, equipped with four satellites. The differential lock is forced or in automatic mode. Dual-band transmission is connected to a dry single-clutch clutch closed type. The steering wheel is under the hood, to the engine. This mechanism is equipped with a hydraulic booster and is connected to the gearbox by means of a worm gear.

Electric circuit and hydraulics

A constant voltage of 12 V is necessary for the operation of electrical appliances. A constant voltage in the electrical network is maintained by the built-in generator, which, in turn, operates from the crankshaft. The connection is made using a belt drive. The MTZ-82 “Belarus” tractor is equipped with a battery. It is installed behind the cab.

For work with the hinged and hook-on equipment the separate-unit hydraulic system is used. Hydraulics is of several types and is installed at the request of the customer. For example:

- power, with positional regulation;

- with mixed controls;

- with mechanical fixation of mounted units.

Cabin

The workplace of the tractor operator MTZ-82 Belarus is highly comfortable. Two types of cabs were installed on this machine. On the old models mounted all-metal cab with a small glass area, designed for one driver.

Then they began to install more overall cab, with panoramic windows. Machine operators called them "Aquariums." This added a little weight to the tractor, but it made the workplace more comfortable.

For work in winter time the heating system is provided. The ventilation of the tractor is carried out naturally. Brushes-cleaners are installed on the rear and front windows.

In the cabin there is a steering, levers responsible for the work of additional equipment, instrumentation.

It is worth noting the installed sensors that monitor the roll of the machine. This significantly reduces the risk of overturning the tractor.

Specifications:

Modification overview

The MTZ-82 Belarus tractor was produced in several versions. Each modification was intended for certain types of work. Among the most popular are the following models:

- MTZ-82 R. This tractor Belarus was designed to perform various work in the rice fields. Considering the specifics of the work, the model had a higher ground clearance, additional final drives and a wide wheelbase. The weight of the car was undervalued.

- MTZ-82 N. The machine was designed to work on steep slopes. Tipping cars can be avoided due to low center of gravity. You can note and low fuel consumption.

- MTZ-82 K. This tractor from the “Belarus” family almost completely repeats the previous model. Of the additions worth noting swing side transmission. They provide car stability.

Advantages and disadvantages

All modifications of MTZ-82 Belarus are distinguished by good maneuverability and high maneuverability. It can be noted and low fuel consumption. The tractor is easy to operate and easy to maintain.

The versatility of the machine is simply amazing. The tractor is used by public utilities for cleaning the streets and laying communications. In agriculture, the machine performs sowing and harvesting work, it can be aggregated with a feed dispenser and used on cattle farms.

It is used in construction, mining and logging. Thanks to good maneuverability, the tractor can work even in confined spaces, for example, in greenhouses or gardens. At the same time, fuel consumption, even at maximum engine loads, is minimal.

Not without flaws. There are leaks in the fuel tank, stiff suspension and lack of air conditioning. In fairness it should be noted that the build quality depends on the manufacturer. Most of all claims to tractors "Belarus", which are collected in Elabuga.

In general, it is a reliable car with excellent maneuverability and an attractive price. With regular maintenance, there are usually no problems with the machine..

Belarusian quality is a topic of special conversation. It is no secret that to this day the products manufactured in this former Soviet republic are still famous for their highest quality workmanship. And we are talking not only about food and textiles, but also agricultural machinery as well. In this article, we will discuss in detail the MTZ-82.1 tractor, its features, characteristics and user reviews.

History reference

Tractor construction in Belarus moved to a new level in 1970, when the production of MTZ tractors began on the order of the USSR Council of Ministers. It was at that time that the government decided to produce a very powerful tractor of tilled type. The basis was taken MTZ-50. The design of the machine has undergone numerous changes, the cabin has also been upgraded, the skin has been installed, the newest engine with higher power has been installed. The first tests of MTZ-82.1 were carried out in 1972 and were quite successful. On the basis of these test races, a list of aggregated components and parts was formed, and also about 230 fixtures were created, oriented towards the performance of various types of work. In this case, the speed of movement of the tractor reached 30 km / h, which made it possible to use it for transport work.

First swallow

The first described car was released by the Minsk plant in 1974. Already at the initial stage of operation, users began to speak very positively about the tractor, and the engineers decided to continue to increase the production of this equipment. For four decades of its release, MTZ-82.1 began to process the fields of almost all continents of our planet. In particular, these tractors are popular in Asian countries, Africa and South America.

The main purpose

The machine was originally designed to work in the fields. Although, in principle, it is quite multifunctional and is a fully driven middle tractor. He is quite capable of sowing various crops, harvesting them, and plowing fields and plowing. Very often, a tractor equipped with attachments and a trailer is used to move a variety of goods, as well as road or other earthworks.

Some nuances

MTZ-82.1 can be operated in almost all weather and climatic conditions. In essence, this machine is an exact copy (in terms of functionality) MTZ-82. The only significant difference is only the increased cab volume of the model with index 1.

In general, the model 82.1 and according to its external data and technical characteristics, has the form of a semi-frame structure, in which the rear running wheels have a much larger diameter in comparison with the front ones. The motor, in turn, is located directly under the driver's cabin.

Engine and gearbox

The fuel consumption of the MTZ-82.1 is quite insignificant due to the presence of the D-243 diesel unit, which, like the tractor, is also produced at the Minsk plant. Engine power is 80 horsepower, which allows the car to travel at a speed of 35 km / h and in parallel with this to use attachments to perform the required work. The required maintenance is minimal.

Despite the fact that the engine is four-stroke, a tractor with an electric starter equipped with a preheater is installed in the tractor. A liquid cooling system is also available, which allows the engine to be started both in severe frost and in heat.

As for the checkpoint, until 1985 this tractor was completed exclusively with a mechanical type transmission, in which the number of gears was not more than 18 × 4 for the front wheels and 16 × 4 for the rear ones. Nowadays, locking the rear axle can be done using a hydraulic system. Reliable differential stopping and its fixation make it possible to increase the maneuverability of the vehicle.

Hydraulic system

It includes the following basic elements:

- Hydraulic type NSH-32.

- Hydraulic power clutch weight (used for attachments).

- Power and position regulators.

- for direct control of the distributor and hinge.

All these nodes have the ability to control from the driver's cabin with the help of pedals and levers.

The main essence of the hydraulic equipment of both the new model and the used MTZ-82.1 tractor is a high-precision adjustment of the position in space of the attachments used on a wide variety of soil types and with different

Directly on the regulators are sensitive sensors that react to any change in the spatial position of the attached module and thrust. In general, the tractor's hydraulic system makes it possible to increase the productivity of the tractor and improve the quality of its work (for example, to guarantee uniform plowing of the earth with the same depth).

Instrumentation

MTZ-82.1 is new equipped with panels with devices, which, in turn, can be both autonomous and be part of a combination of equipment. In addition, there are blocks of special control lamps and fuse, with fusible links for reliable protection of all existing electrical circuits.

For example, the engine coolant temperature gauge has warning lights of a different color:

- Working range (from 80 to 100 degrees Aim) - green.

- Non-working range (up to 80 degrees) - yellow.

- Over 100 degrees Celsius - red.

Oil pressure in a diesel engine should be within 1 - 5 kgf / cm 2. A pressure surge of up to 6 bar is allowed at the time of starting the cold engine. However, if the emergency lamp continues to burn and in the process of further work, you should immediately stop the engine and proceed to troubleshoot the problem. In turn, the pneumatic system operates in the range of 5–8 kgf / cm 2 and includes a compressor and a distribution valve to control the differentiated operation of the brake system.

Technical indicators

Any (second-hand including) has the following technical data:

User Opinion

Regardless of where the MTZ-82.1 second-hand tractor was purchased (Avito, other sites or directly at the factory), many farmers noticed that the machine's performance is not very high when processing large fields, over 80 hectares. The weakness of the work of the third and sixth gears at times of heavy loads was also noted.

In turn, the engine is not too susceptible to the quality of fuel consumed, but if the quality of diesel fuel is too low, the engine may well stall or not start. In this case, as practice has shown, the problem is eliminated by adjusting the injectors or changing diesel fuel.

Of the positive qualities of the tractor, it is worth noting its almost absolute “indestructibility”, since neither heat, nor cold, nor road, nor dust, nor any possible precipitations have any effect on it. In addition, the machine is quite easily combined with many attachments and is very easy to operate. Drivers also noticed a rather high level of cabin comfort, which fully complies with all current ergonomic standards and requirements.

Running in

Today, the Avito tractor 82.1 MTZ can be purchased completely new. It is important to know that the new car must be, continuously, run in for at least 30 hours. This procedure is mandatory because it allows all, without exception, parts of the tractor to work hard and ensure a subsequent long service life. It is forbidden to start a new, unrolled diesel engine from the tug to avoid rapid wear of its components.

Maintenance

Planned work is carried out according to the following scheme:

- Checking the fan belt tension (after 125 hours of operation) - the belt deflection should not exceed 15 - 22 mm when pressed on it with a force of 40 N.

- Control of the free motion of the clutch pedal (after 500 hours of operation) - 40 - 50 mm along its cushion.

- Measurement of backlash of the steering wheel (after 500 hours of operation) - in no case should it exceed 25% while the engine is running.

- Covering the cylinder head mounting bolts (after 1000 hours of operation) - the tightening torque must be between 19 and 21 kgcm.

- Checking the tightness of the nut of the intermediate support safety coupling - the coupling must be able to transmit a torque of 40–80 kgcm.

- Monitoring the radiator coolant level (after 10 hours of tractor operation) - it should be no more than 50 mm below the edge of the filler neck.

- Changing the oil in the engine crankcase - after 500 hours of continuous operation.

- Replacement of the filter element of the fine filter - after 1000 hours of continuous operation.

- Condensate from the receiver is drained every ten hours of operation.

- Timely move in the summer and winter to the appropriate varieties of oil and grease.

Conclusion

When purchasing MTZ-82.1 on Avito or elsewhere, always remember that this tractor can be actively used as a loader, excavator, bulldozer, and even in some cases a combine. And given its relatively low cost, it becomes clear why the demand for it has remained steadily high for so many years.