Soviet tractors description and characteristics. Museum of tractor history. Chelyabinsk Tractor Plant Before the War

In the early 30-ies for the mechanization of labor-intensive work on cultivating tilled crops, the Universal tractor was developed. The tractor "Farmol" of the American company "International Harvester" was used as a basis for the design. The modifications were made to the design of the prototype: components and materials of domestic production were used, a new calculation method and technology of gearing were applied. A front two-wheeled bridge of original design was designed for processing low-growth tilled crops .

It is known that only one of the original prototypes of wheeled tractors, this one, still exists. The owner of the farm used universal tractors. Satsler and Jantsen now worked together to develop the tractor belt. But these higher operating speeds exaggerated the steering problem and showed the need for a track suspension. The use of this updated system provided stable tractor steering characteristics at much higher working speeds and speeds; and he continued to supply energy to both tracks even during the turns.

In the early 30-ies for the mechanization of labor-intensive work on cultivating tilled crops, the Universal tractor was developed. The tractor "Farmol" of the American company "International Harvester" was used as a basis for the design. The modifications were made to the design of the prototype: components and materials of domestic production were used, a new calculation method and technology of gearing were applied. A front two-wheeled bridge of original design was designed for processing low-growth tilled crops The tractor had an enlarged clearance, narrow wheels and a track corresponding to the size of most rows taken for row crops The power unit is a kerosene carburetor engine.As a supplementary equipment, a crane lift for mounted cultivators and other implements could be installed on the tractor, and since 1950, for the first time in the USSR, tractors were equipped with hydraulic hoists for mounted agricultural implements. The tractor "Universal" is similar to the tractor СХТЗ-15/30.

For the first time in the world, the domestic designers developed two modifications of the tractor Universal: U-1 with the front wheels adjoining - adapted for inter-row processing of high-growth crops (irrigated cotton, sunflower, maize); U-2 with front wheels arranged - suitable for inter-row processing of sugar beet and other low-growth tilled crops. In the 1940s, two more modifications were made to the tractor, "Universal: U-3 - for inter-row processing of rain-fed cotton, U-4 for the installation of cotton harvesters." This model was used for the first time in the USSR to install wheels with non-pneumatic tires. "Universal" in the domestic tractor construction was launched a new direction - the production of row tractors.

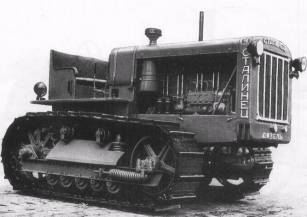

Model C-60 was created as a powerful tractor with high traction and cross-country ability. The prototype was chosen one of the best in the world of caterpillar tractors "Caterpillar-60". For the production of C-60 in 1932 was commissioned Chelyabinsk Tractor Plant-giant with the mass production of mass production. The frame of the tractor-semi-frame is formed by the transmission case and the engine subframe. On the tractor was installed a soft seat for the tractor driver and assistant. Engine - carburetor four-stroke four-cylinder in-line, fuel - naphtha. The clutch is a two-disk clutch. Suspension - semi-rigid. Caterpillar - compound with stamped links and shoes made of special rolled metal. The tractor had a power take-off shaft and a pulley. C-60 was widely used not only in agriculture, but also in construction, and was also used for army needs. In the production process, the C-60 was significantly upgraded: the carburetor engine was replaced by a slightly larger diesel engine. The first domestic diesel tractor of mass production was produced under the brand S-65. The non-compressor diesel with a pre-chamber mixture was started with a gasoline-powered starting engine with electric ignition. To install the diesel tractor chassis has also been upgraded: the transmission ratio and the length of the tracks have been changed. In addition to the basic model of the C-65, two modifications were made: SG-65 - gas-generating and C-2 - transport.

In the mid-1930s, it became necessary to create a mass caterpillar agricultural tractor. Taking into account the needs of the army and other branches of the national economy in caterpillar tractors, tractors at the Stalingrad Tractor Plant, together with NATI, unified agricultural and transport modifications of the caterpillar tractor were developed. The first mass-produced tractor of the original domestic design was developed taking into account the best achievements of the world and domestic tractor construction. SCHTZ-NATI had a frame structure with a riveted frame consisting of two spars and four crossbars. Elastic suspension on four balanced carriages with coiled spring springs. The cabin is half-closed. The engine and power train are mounted on the frame in three points. The power unit is a four-cylinder kerosene carburetor with water cooling. The gearbox is a three-way gear, the caterpillar is made of links cast from high-manganese steel. For a whole decade, the SHTZ-NATI remained the most common caterpillar tractor, only in 1949 it was replaced by the DT-54, which, by arrangement, power transmission scheme, running system and skeleton, retained continuity with the SCHPN-NATI and differed from it with a diesel engine, a closed cabin and the location of the fuel tank from the rear.

Development of the construction of a medium-duty caterpillar tractor began in the late 1930s. The war interrupted these works. In 1943, the government, anticipating the great need for tractors after the war, decided to resume work on the development of new tractors and the construction of new tractor plants. In accordance with this, at the height of the war in NATI, the development of the design of a new medium-sized tractor began, and prototypes were created and tested. In parallel with the design of the tractor, in Lipetsk was started construction of a plant for its production. The designers of the construction of the Lipetsk Tractor Plant joined the development of the tractor. At the same time, a diesel engine was developed at the NATI for a medium-duty tractor. On July 1, 1944, the Lipetsk Tractor Plant began the production of Kirovets-35 tractors with a carburetor engine, and in 1947 switched to the production of a KD-35 tractor with a diesel engine, Rama KD-35 - riveted, suspension - semi-rigid, stars, spring - sheet. In the process of production, the tractors were equipped with closed cabins. A four-cylinder diesel with a vortex-chambered mixture and an all-regulator has a low fuel consumption and high reliability. For a long time the engine was upgraded many times. Modifications of this engine were used on wheeled and caterpillar tractors of various types, on road construction machines, power stations and other stationary installations. In 1950, at the Lipetsk Tractor Plant, the modification of the KD-35 tractor KDP-35 tractor began, which differed from the prototype with an enlarged clearance, a wider track and a smaller track width.

The T-38 tractor is the result of the modernization of the KDP-35 tractor, which has increased the strength of the running system as a result of the use of roller bearings and rubber-metal end seals in rollers and guide wheels. The use of centralized lubrication of rollers from a common oil tank has significantly reduced the time required for lubrication. Torsion suspension of the trolley carriages made it possible to increase the smoothness of the stroke, especially when working across rows. As a result of the rotation of the lower gearboxes of the final gears, the arrangement of the center of gravity was improved, which increased the stability of the tractor when working with mounted implements.

When upgrading, the engine power was increased due to an increase in the speed of the crankshaft. The upgraded version received the T-38M brand. Tractor T-38M was used mainly in beet production. Working in narrow rows of sugar beet crops with wide-spread hinged and trailed machines, and when harvesting - with a three-row combine, it provided high efficiency and economy.

To increase the economy and reliability of the main arable tractor on the basis of SCHTZ-NATI a new tractor was created, in which the carburetor engine was replaced by a diesel engine of the same dimension. This tractor received the DT-54 brand. The four-cylinder non-compressor diesel tractor DT-54 had a vortex-chambered mixture. The vortex chamber, cast in the block head, was not machined. The volume of fuel supplied to the cylinders was regulated by a centrifugal all-regulator with a corrector. The diesel engine was started by a starting engine. The decompressor is dual-wired. The power train and skeleton of the DT-54 tractor basically did not differ from the STIP-NATI. In the running system, in contrast to the SXTZ-NATI in the DT-54 support rollers, end metal self-seal seals were used. Due to the high continuity of the construction of the DT-54 tractor with the SCHTZ-NATI, the transition to the production of the new model was carried out at factories without stopping production, only with a small decrease in output in the first year. When upgrading to the DT-54 was installed a closed cabin. After installation, for the first time in the world for crawler tractors, a hydraulic mounted tractor, the tractor was manufactured under the DT-54A brand. On the basis of this tractor at the Volgograd, and then in the Altai Tractor Plants, the swamp-type modification DT-55A was produced. High traction and cross-country ability, as well as low cost, provided the DT-54 in the 50-60s with the greatest popularity among domestic tractors in agriculture.

The first small-sized domestic tractor of mass production is KhTZ-7. This is one of the first tractor in the domestic tractor construction, on which pneumatic low pressure tires and a hydraulic hinged system were installed. HTZ-7 had a classic layout, frameless skeleton and was adapted to work both forward and reverse. For backward movement, the tractor was able to change the position of the driver's seat and reverse control. The design of the tractor made it possible to adjust it for work both in the aisles of row crops with increased road gleam, and in the gardens with a reduced height of the tractor. All the necessary adjustment for this could be done in the field. The tractor was equipped with a two-cylinder petrol carburetor engine. Final drives could be turned over, which allowed changing the height of the tractor by 207 mm and ground clearance. The tractor had a power take-off shaft and a pulley. DT-14, created on the basis of KhTZ-7, differed from it mainly by installing a more powerful single-cylinder diesel with water cooling. In the process of modernization of the DT-14, an electric engine start was set up on it and a unified, separate, modular hinged system was installed.

DT-20 is the further development of the DT-14 design with a more powerful engine of a larger working volume. The tractor had increased speeds. In connection with the increase in speed, a third brake pedal was introduced to jointly act on both brakes, as well as the foot accelerator. Like HTZ-7 and DT-14, four adjustments provided different sizes of the base and clearance, as well as the ability to work in reverse.

The engine and power transmission of the self-propelled chassis are integrated into one unit, installed at the rear of the car behind the seat. The two-branched frame is free from chassis mechanisms and is intended for placement on it of hinged agricultural machines or a dumper platform. Attached machines are placed between the axes of the front and rear wheels of self-propelled chassis, which allows work in the aisles with small protective zones and provides a good visibility of the working bodies. On the self-propelled chassis DSSH-14 was installed unified with diesel tractor DT-14 engine. The chassis is equipped with a hydraulic hinged system, two remote hydraulic cylinders and pneumatic low pressure tires. The main power take-off shaft - with a semi-independent drive, three power take-off shafts - with a synchronous drive. For the work with planting material, a speed reducer is used. ДВСШ-16 - modernization of the self-propelled chassis DShS-14, which differs from the prototype by a double-cylinder diesel engine of air cooling of high power with electric start-up. It is also possible to install a drive pulley.

Self-propelled chassis T-16 - the development of the design DVSH-16. A distinctive feature is a gearbox providing speed reversal. For stationary operation, a pulley with drive from the main power take-off shaft is provided. As a result of the modernization of the T-16, the engine's power was increased and its design was improved. The chassis was manufactured under the T-16M brand, it was equipped with a two-cylinder air-cooled diesel engine with direct injection (piston chamber). The gearbox provides higher speeds on all gears. The carrying capacity of the platform is increased and the wheels of the increased size are installed. A frame with awning, sidewalls and doors is provided.

In the 1950s, the construction of row tractors was significantly improved. In these years the series introduced pneumatic tires, hydraulic attachments, diesel, adjustable track, the maximum speed increased from 8 to 18 km / h. Pneumatic tires and hydraulic system for the first time in the USSR began to install on tractors "Universal", and all of the above innovations were introduced on the DT-24. The DT-24 tractor is designed to work in a 2- 4 row system. Three models of tractors were produced: DT-24-1 for processing high-growth tilled crops; DT-24-2 - for inter-row processing of high-growth tilled crops and DT-24-3 - for processing cotton crops. On all models of tractors ДТ 24 there is a two-cylinder, non-compressor, vortex-chamber diesel engine, which is started manually with a gasoline trigger by means of a handle. The starting device is equipped with a carburetor and magneto. The upgraded DT-24 was manufactured under the T-28 brand with a more powerful engine (mainly due to increased fuel supply). To clean the oil in the engine lubrication system, a centrifuge with a hydraulic drive is installed. On the tractor there is a unified separate-aggregate hydraulic system.

The first cotton-growing tractors of the Vladimir Tractor Plant were based on the Universal tractor, then as modifications of the DT-24 tractor. Tractors Т-28Х, Т-28Х2, Т-28ХЗ, Т-28Х4 were produced on the basis of the chassis of the T-28 tractor. The T-28XZ tractor with two driving rear wheels and one front steering wheel, thanks to the additional on-board gears at the rear wheels, has a high ground clearance. Four-cylinder diesel - with an unshared combustion chamber and air-cooled. The tractor is equipped with a rear power take-off shaft with a dependent and independent drive, a side power take-off shaft with a synchronous drive. The upgraded T-28XZ tractor was manufactured under the T-28X4 brand, had a high-power engine, a high agro-technical clearance of 825 mm, and a rear wheel gauge adjusted with a hydraulic cylinder. In the course of further modernization, the engine power of the T-28X4 tractor was increased to 60 hp. and the speeds of movement are increased. The tractor was manufactured under the T-28H4M brand.

In the first in the domestic tractor-building MTZ-2 was designed as a medium-sized wheeled tractor for row work in the 4-6-row system. The tractor is equipped with pneumatic low-pressure tires and a hydraulic hinged system. The MTZ-2 tractor is a classic configuration and a semi-frame design with a four-cylinder diesel engine, which differs from the engine mounted on the KD-35, a lightweight radiator and a crankcase. The tractor is equipped with a power drive shaft with a dependent drive, a pulley for driving stationary machines and a speed reducer with: two interchangeable sets of gears, the track of the front and rear wheels is adjustable and wide.

In the production process the MTZ-2 tractor underwent modernization: an engine with a capacity of 40 hp was installed.

The MTZ-2 tractor became the first model of the mass wheel universal tractor of the Minsk Tractor Plant.

The YUMZ-6L / 6M tractor was developed on the basis of MTZ-5. The engine can be delivered in two trim levels: with an electric starter (UMZ-6M) or with a starting motor (UMZ-6L). The modernized tractor YUMZ-6L / 6M is manufactured under the YUMZ-6AKL / 6AKM brand, it is equipped with a speed reducer (optional), an independent power take-off shaft, a power steering with an adjustable steering column angle, a hydraulically operated split-aggregate system with an automatic coupler . On request, the tractor is equipped with additional equipment: wheels for rowing work in narrow rows, semi-tracked; preheater and others.

Tractor T-40-traditional layout and semi-frame construction, its versatility is provided by the ability to adjust the ride height and track. The tractor has a four-cylinder, air-cooled engine. The engine has a combustion chamber of an undivided type. The double-acting clutch provides independent power take-off drive. Transmission 7-speed, with the reverse of all gears. Power steering. The closed all-metal cabin is equipped with a fan and a windshield wiper. PTO shafts with independent and synchronous drives for the mechanisms of aggregated machines. On the basis of the T-40, a modification of the T 40A with four driving wheels has been developed. The front drive axle with two freewheel clutches is automatically engaged at a certain amount of skidding of the rear wheels. The portal design of the front axle allowed to preserve the quality of the universal tractor. In the process of production, the T-40 and T-40A tractors were modernized and began to be produced under the T-40M and T-40AM brand, whose engine power is increased to 50 A from the new-design tractor cab. The rigid frame for driver safety provides better visibility.

The MTZ-50 tractor is a further development of the MTZ tractors' standard size of the classic layout. It is equipped with a high-power engine, power steering, sprung front axle, hydraulic linkage weight increase, differential lock mechanism, closed cab. On request, the tractor is equipped with a pneumatic brake system for transport trailers, a manual brake drive. MTZ-52 with four driving wheels - modification MTZ-50, completely preserved the versatility of the basic model due to the same with it the ground clearance and adjustable track of the front wheels. The front wheel drive with an automatic freewheel clutch is activated when the rear wheels are slackened. On the basis of MTZ-50 a family of unified modifications for different purposes was created: with all driving wheels; cotton-growing, steep, semi-caterpillar, caterpillar-vineyard and beet-growing. Common for all wheeled and caterpillar modifications are the main components of the MTZ-50 tractor: engine, clutch, gearbox, hydraulic system, electrical equipment, power take-off shafts, etc. The degree of unification with the base model is 80-97.5% for wheeled and semi-tracked and 50-65% for crawler tractors. In the production process, MTZ-50 and MTZ-52 tractors underwent a phased modernization. So, since 1980 new frame cabinets of the improved appearance began to be installed and tractors began to be produced under the MTZ-550 and MTZ-552 brands, and with the increase in engine power up to 60 hp. - MTZ-560 and MTZ-562. To meet the needs of the market, low-profile tractors MTZ-530/532 with a capacity of 65 hp were created and started to be manufactured on the basis of MTZ-560 and MTZ-562 tractors. and their garden modification "Belarus-680".

The T-75 tractor was created as a result of the modernization of the DT-54A: the engine of increased power, the frame was strengthened by the installation of the front bar and braces, the number of forward gears was increased, the starting motor with the electric starter, the two-seater cabin of the closed type with heating and ventilation. The structures of the rear axle and running system T-75 and DT-54 are basically similar. T-74 - modernization of the T-75 tractor, differs, mainly, by installing the engine of a new more advanced design. To maintain the former location of the center of gravity of the tractor using a lighter engine, a bumper is installed on the front bar.

Tractor T4 is designed as a plow tractor for work in the steppe regions of Siberia and in the zones of irrigated and irrigated agriculture in Central Asia, characterized by an increased specific resistivity of the soil. A single-stage planetary steering mechanism ensures a reduction in track, while improving the conditions for the assembly of the tractor with agricultural machines. The restaurant is equipped with a separate-aggregate hydro-mounted system, as well as a power take-off shaft. Closed metal cabin with soft adjustable seats and ventilation and heating system. The upgraded T-4 tractor is produced under the T-4 brand with a high-power engine, a semi-rigid suspension on one transverse balance spring, and a preheating pre-heater is installed before the engine is heated.

The construction scheme of the tractor DT-75, in comparison with the tractors SCHTZ-NATI and DT-54, has not changed, but the main units have been improved: the engine, the power train and the cab. The construction of the tractor is adapted to the assembly with mounted agricultural machines, mainly due to the installation of the hydraulic attachment system and the reduction of the overall width of the tractor. Four-cylinder diesel engines of the Kharkov motor plant Serp i Molot (DT75, DT-75V, DT-75N) and the Altai motor plant (DT-75M, DT-75MV, LT-75ML, DT-75D) with water cooling and starting a motor with an electric starter. The main clutch is a dry, two-disc, permanently closed type. Rear axle with two single-stage planetary turning mechanisms, with brakes of sun gears and two stop brakes. Separate-aggregate hydro-mounted system with attachment of agricultural implements to 2-hour 3-point circuits was installed. Cab of closed type, metal with heating and ventilation. Tractors are supplied in various configurations, a swamp-type tractor is created and produced on their basis. For a number of years, the shuttle-reverse steep-roll tractor was also produced.

The design of the T-25 tractor was developed with the modernization of the T-20, the traditional layout was retained and a two-cylinder air-cooled engine was installed. The wide universality due to the adjustable rings and agrotechnical clearance, the reversibility of the main gears is preserved. There are three changes in the tractor height: basic, low and high. An 8-speed gearbox is installed, as well as a dependent and synchronous power take-off shaft. Start the engine from the electric starter, and the incandescent light. The modernized tractor T-25 is manufactured under the T-25A brand. Depending on the equipment, a cab can be installed on the tractor, the safety net canopy. Cabin - all-metal single, with safety cage, heater, ventilation system, with windshield wiper.

The MTZ-80 tractor is designed for the modernization of MTZ-50. Unification of the details of these tractors is 70%. The tractor is equipped with a liquid-cooled diesel engine of increased power. An additional gearbox is added to the gearbox, doubling the number of gears. Reversing differential with automatic locking, rear power take-off shaft is made by two-speed. The universal pneumatic system serves for the drive of the trailer brakes and tire inflation. The hydraulic system is supplemented with mechanisms of power and position control of the depth of the stroke.

The tractor is equipped with tires of increased size. Sealed with a rigid frame, the cabin is equipped with a single seat, electric wiper, heating and ventilation system.

The MTZ-82 tractor MTZ-80 modification is equipped with a leading portal front axle for increased cross-country capability, a safety clutch and a mechanism for deflecting the freewheel interaxle are used in the front axle drive. The MTZ-80 tractor and its modifications have been continuously improved: a more comfortable cab has been installed, a gearbox with switching without a power flow gap, a hydrostatic power steering, brakes with brake discs increased to 205 mm in diameter. A gradual improvement in the appearance of new types of hoods, modern cab elements, a more ergonomic cabin interior with simultaneous increase in power and a reduction in fuel consumption became the basis for the appearance of the upgraded models MTZ-890/892, MTZ-900/902 and MTZ-950/952. On the basis of MTZ-80/82 tractors special modifications have been created and produced: MTZ-80X-cotton; MTZ-82N - low-pass, MTZ-82R - rice, caterpillar, etc.

The T-70S tractor was developed during modernization of the T-54S with the use of MTZ-80 tractor units: engine, clutch, transmission, electrical equipment and hydraulic systems. The T-70S tractor has increased energy saturation and a wide range of speeds. Equipped with a two-speed power take-off shaft with independent and synchronous drives. Suspension of the tractor is semi-rigid, with front and rear suspension of the frame torsion bars. The cabin is sprung with a rigid frame, equipped with an evaporative-type air cooler.

The construction of MTZ-102/100 tractors was created as a result of a thorough modernization of the MTZ-80/82, a box was used with a gear change without a power flow gap, the engine power was increased as a result of the application, turbo-supercharging, the steering was equipped with a hydrovolume drive, the load capacity of the hinged devices, installed tires of greater carrying capacity, which together with the increased traction mass provide working traction up to 2 tons. The working position of the mounted implements is regulated by a high-altitude, power, position on-line and mixed methods. Tractors MTZ-102/100 are constantly being modernized. Samples with more modern forms of the hood and elements of the cabin with an improved interior are produced under the brand MTZ-1025.

The T-150K tractor has four driving wheels of equal size, the turn is carried out also due to the articulated frame. The vertical hinge of the frame serves to turn the tractor, horizontal - to adapt the wheels to the terrain. Transmission 12 -speed, 3-band. Brakes - wheeled shoe with pneumatic booster, pneumatic drive system of trailer brakes. The power take-off shaft is independent, 2-speed, rear. By order of the customer, the tractor is equipped with a diesel engine with a starting engine or an electric starter, a gearbox with a hydraulic gear change without a power flow gap, a speed reducer for working with artophelploscopes or a transmission with creeping speeds for working with earth-moving machines. Twin wheels and dozer equipment with a swivel blade can also be installed.

The tractor DT-175S is developed on the basis of DT-75 tractors with preservation of the classic layout. A special feature of the design is the presence in the transmission of a torque converter, which automatically regulates the speed of the tractor's forward motion. The hydrotransformer complex, blocked. The transmission is mechanical. The main gear, the planetary gear and the tractor's brakes DT-175S are similar in design to those installed on the DT-75 tractors. The tractor is equipped with a six-cylinder V-engine with gas turbine supercharging and intermediate cooling of air. The tractor's power take-off shaft is two-speed dependent. The tractor is equipped with a separate-aggregate hydraulic system, a rear linkage mechanism with automatic coupling and a towing device. The two-seater all-metal sealed cabin is fixed to the tractor frame on a sprung base and shifted to the right of the tractor axle.

The design of the TZOA-80 tractor was developed as a result of the modernization of the T-25A with the preservation of the traditional layout. A new two-cylinder air cooling diesel engine of increased capacity has been installed to increase the throughput and traction qualities - a portal-type leading front axle with automatic inclusion with increased overshoot of the rear wheels, a double-flow clutch, an independent power take-off shaft and disc brakes, a hydrostatic-type steering system, carrying capacity, single cabin (removable, sealed, soundproofed with ventilation, heating, sprung seat). On request, the tractor can be equipped with a universal regulator of plowing depth, a drive pulley, an automatic coupler, a mechanized digging of the hinged system.

The tractors KhTZ-120 and KhTZ-121 are designed on the basis of the T-150K tractor (unification factor of 40%), they have four driving wheels of equal size and front steerable wheels. The gearbox with gear change gears, 12-speed - at the KhTZ-120, and 1b-speed with the shifting of gears without a break in the power flow with the help of hydropodic couplings - at the KhTZ-121. The steering gear is hydrostatic. The front axle is a balancer with swivel wheels. A single-frame frame-safe cabin with a central tractor driver's seat. For operation (power take-off, the engine has a second mode providing operating power of 145 hp (106 kW) .On the customer's request, the tractor is equipped with a front power take-off shaft, a front mounted system, a set of twin wheels with narrow tires 9.5-42 for work with row beams, as well as prefabricated discs for mounting wheels on a track of 2800 mm.

The construction of the tractor LTZ-55A was developed as a result of a deep modernization of the T-40AM tractor: a sealed noise-proofed cab with a ventilation and heating system with a large glazing surface was installed. comfortable adjustable in height and weight of the driver's seat. A more convenient arrangement of controls and a new design distinguishes the tractor LTZ-55A from its predecessor. The gearbox provides a reversal of all gears, the steering column is adjustable, the engine load is controlled by an electronic alarm.

The design features of the tractor provide high technical reliability, simplicity and convenience in service, work in any geographical areas with minimal operating costs. Tractors LTZ-60AV h LTZ-60AG) differ from LTZ-55A by installing engines with water cooling capacity of 60 hp. Rybinsk Motors JSC (LTZ-BОАВ) and the Minsk Motor Plant (ЛТЗ-60АБ), a hydrostatic steering drive with a cylinder built into the trapezium, and a water heating system.

The tractor has a traditional layout, a two-cylinder air-cooled diesel engine with direct fuel injection, a mechanical reversing gearbox, to increase the throughput - the differential lock. The tractor cabin is a single-frame safe frame type sealed heat and noise insulated with heating and ventilation. The steering column is adjustable in height and angle.

The MTZ-1221 tractor was designed as a result of a thorough modernization of the MTZ-102. The increase in power is achieved by the use of a 6-cylinder engine of the same dimension, the rear drive axle is reinforced by the installation of additional planetary final transmissions. The front drive axle is upgraded for heavy duty applications. The working position of the implements is regulated by force, positional and mixed methods. The lifting capacity of the hinged system has been increased up to 3000 kg, front tires - 14,9-24, rear ones - 18,4-З8. The tractor pulling force and the size of the attached implement ensure efficient assembly of a class of tractors with a set of agricultural machines. A number of measures have been taken to improve the working conditions of the tractor operator.

At present, tractors LTZ-133 of the integrated circuit are produced in small series. On the tractor LTZ-155, all driving and steering wheels of the same size are installed. The engine is pushed forward on the front axle, and the cabin has a central location. At the same time, the tractor's mass distribution in static is 60% on the front axle and 40% on the rear axle. The space behind the cab, above the rear axle, is used to accommodate technological equipment. The frame of the tractor is semi-frame. Original steering control of all steerable wheels. Synchronous drive of the front and rear wheels is realized through the interaxial gear differential with electrically controlled locking and the self-locking differential of the front axle. Braking of the front wheels is carried out simultaneously with the rear wheels. The control station in the cabin is made quick-convertible. A variety of the range of equipment available on request (front attachment, front, rear top and side power take-off shafts, narrow twin wheels, speed reducer, towing devices) allows expanding the scope of the tractor.

The VT-100 tractor differs from the DT-75N, on the basis of which it is created, increased energy saturation, the use of a two-level engine for operation in the traction and drive modes, the presence of a 5-speed gearbox with gears of constant engagement, a 2-speed power take-off shaft, comfortable working conditions driver, etc. The installation of a reverse gear and a speedometer allowed to significantly increase the number of working transmissions. The cab of the tractor with increased comfort and modern interior is equipped with an evaporative-type air cooler. On request, a reversible control station is installed on the tractor.

Tractor T-170M1.03-53 is developed on the basis of industrial tractor T-170M. In contrast to the basic model, the T-170M1.03-53 engine is equipped with an increased power engine, a rear agricultural hinged system and a frame from the T-170B swamp-type tractor, as well as 6-track crawler carriages, 600-mm-wide tracks, , a 2-speed power take-off shaft is installed. On the front, the tractor is equipped with a ballast counterweight or bulldozer blade, which increases the longitudinal stability and improves the position of the pressure center during field work and transport operations with attachments.

The tractor is equipped with a three-cylinder D-130 air-cooled diesel engine and a front drive axle, a low cabin (the tractor's height is 2350 mm) allows it to be used for mechanization of work on livestock farms and hothouse farms throughout the year. On the tractor, progressive solutions are realized: transmission with synchronized gearbox, front portal type gantry with automatic switching on with increased skidding of the rear wheels; disc brakes; hydrostatic power steering; independent three-speed (540, 750 and 1000 rpm) power take-off shaft with switching to synchronous; cabin with a rigid frame, increased vibration and noise insulation and improved working conditions; hydro-mounted system of increased payload. Various configurations for the order are envisaged, including equipment with safety cage with awning instead of cab, automatic coupler.

The goal of the development is the creation for agriculture of a mobile traction-energy facility of Class 1.4 of the classical layout, maximally unified with an LTZ-155 tractor of the integrated circuit, Class 2.0. On the tractor there are many progressive components, borrowed from the LTZ-155 tractor: a single-disk clutch, a gearbox with helical gears of constant engagement, 4-diapasoned, with 4-gears within the ranges on the move, synchronized on request; rear driving axle; PTO shafts; attachments. Other advanced technical solutions: hydrostatic power steering with built-in trapezium hydraulic cylinder and separate oil bath; stop disc wheel brakes with hydraulic servo, locked with a central brake and front axle drive; combined oil bath of the transmission and hydraulic system. By request, the tractor can be converted to work on the reverse; is equipped with narrow dual tires of the rear wheels, traction-coupling devices of various types, front attachment, rear upper and front two-speed power take-off shaft, a chassis hood. The prototype of the tractor is factory tested

The design of the tractor is designed to create a universal tractor of high technical level on the basis of units and assemblies of the YUMZ-6K tractor manufactured in the Russian Federation, including the engine and clutch, body parts and transmission elements, hydraulic hitching systems, etc. MVM- NATI-80 is a classic tractor with all driving wheels. Compared with the analogue tractor UMZ-6K, it has a more powerful turbocharged engine, hydrostatic power steering, unified seat. Installed on the inn, the front drive axle of the original design allows you to increase the angle of rotation of the front wheels, up to 500, while maintaining agro-technical requirements for maneuverability and agrotechnical clearance, with the tires enlarged with increased tire size (11,2-28). For the tractor a new top structure with an inclined hood is developed to improve the visibility of the front working area, as well as a new cab with better workplace organization and a universal information system with a real-speed radar sensor. At present, a prototype of the tractor is manufactured and its evaluation tests are carried out.

The VT-130K tractor was developed on the basis of DT-75N and VT-100 using their engine, transmission case, a number of gears, frame, working equipment, cab elements. The tractor has a new layout with all the leading and steerable wheels of equal diameter. The front wheels are sprung. The engine, transmission, cab and working equipment are installed on the tractor frame. For the VT-130K tractor a gearbox with gears of constant engagement and hydraulically controlled friction clutches is developed. The gearbox has a built-in friction mechanism for the power take-off shaft, as well as switching it to independent or synchronous modes. For the tractor a cylindrical gear differential with forced locking is developed, as well as disc dry brakes with installation on the semi-axles. The drive to the rear wheels through the cylindrical planetary gearbox, and the drive to the front wheels is separated by the beams from the rear axle through the bevel gearboxes, overtaking clamped couplings and final planetary gears. The tractor is controlled by turning the front wheel guides with the help of two power cylinders and additionally turning by means of braking the lagging board. Suspension of the front wheels is individual with coil springs. The VT-130K tractor is at the stage of state acceptance tests, as well as operational tests of the pilot lot.

The layout of the tractor is traditional. Six-cylinder liquid-cooled diesel with. turbocharging and intercooling of air with a four-valve head. The transmission is mechanical, full-range, with on-the-fly shifting by means of hydraulic couplings without breaking the power flow in the entire speed range. The mechanism of rotation with hydropodic friction clutches and disk brakes working in oil. In the running system on each side there are six support rollers with a plastic individual suspension with torsion spring elements. Caterpillars of the forging engagement are two-track, the tension of the tracks is hydraulic. A version of the caterpillar with rubber-metal hinges is provided. A single sealed heat and noise insulated cabin is equipped with means for normalizing the microclimate during the summer and winter periods, with a safety cage. The T-250 tractor passed acceptance tests and in 1994 was recommended for production.

A fundamentally new arrangement of the tractor with a triangular crawler bypass provides, in comparison with the traditional, a decrease in the operating weight, a reduction in the harmful effect on the soil, an optimal arrangement of the center of mass and the possibility of aggregation with heavy mounted machines and implements. A constant power motor with a large torque reserve, a transmission with all gear shifts on the move, a stepless turning mechanism and a comfortable noise- and vibration-proof cab. Rubber-reinforced asphalt caterpillars significantly expand the scope of use of the tractor. Instead of rubber caterpillars, steel with rubber-metal hinges can be installed, and instead of a stepless turning mechanism, a traditional slewing mechanism with wet-type side clutches is used. Experimental tractor samples are laser-polsvye and operational tests.

1. T-28 - a brand of wheeled tractor manufactured by the Vladimir Tractor Plant from 1958 to 1964

Despite the fact that the wheeled tractor was almost ready for production, the managers canceled it in favor of a belt tractor, appreciating its potential, to the great shock of many engineers who worked on a wheeled tractor. Initially, the senior management believed that the steel version was retained as an alternative to the economy of a tractor with a rubber belt.

But they decided to stick to this, and most potential customers did not seem to mind or notice. However, both original prototypes are now in the hands of the private collector, although no tractor is completely complete, since the parts were pirated at different times during ongoing development projects on Proof. But they were saved from a warehouse of waste and remain symbols of an important milestone in agrotechnology technologies.

2. DT-20 is a brand of wheeled tractor manufactured by the Kharkov Tractor Plant from 1958 to 1969

3. KhTZ-7 - universal garden and truck tractor, produced by the Kharkov Tractor Plant from 1950 to 1956. The first Soviet small-sized tractor

The "caterpillar" type machine was developed for use on soft ground. The weight of the machine "caterpillar" is distributed over a much larger surface area of the tracks, which allows the machine to move along soft layers. The wheel machine has a very limited surface area on which its weight is distributed. In addition, farmers and ranchers in the American West found that the caterpillar tractor had better traction with the ground than the wheeled tractors, and could pull more weight for this horsepower.

And the caterpillar tractor was much more stable on uneven or hilly ground, where farmers and ranches grew wheat and other agricultural products. A few years later another Englishman used the ideas found in the first patent, and applied the "caterpillar" tracks to the thirty-ton steam tractor, but the experiment was unsuccessful. The inventor was also awarded a US patent, but the inventor did not have enough financial resources to make the invention successful.

4. T-5 (information about the model was not found)

5. T-38 - universal tractor caterpillar tractor manufactured from 1958 to 1973 (with modification of T-38M) Vladimir and Lipetsk Tractor Plants

Lombard began construction of "caterpillar" tractors, working on steam boilers. Lombard tractors were created to transport timber in the forest in Maine. In those days logging was carried out in the winter, because on a horse there were fewer horses to pull logs loaded on a large snow sled. Sledges were strained on roads built from snow. Tracks on which runners on traverses traveled along snow roads were finished with the top of the ice to reduce friction or resistance between the heavy sled and the snow road under them.

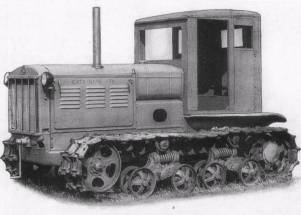

6. KD-35 - a rowed crawler tractor manufactured from 1947 to 1960 by the Lipetsk Tractor Plant, since 1950 by the Minsk Tractor Plant and since 1951 by the Brasov Tractor Plant (Brasov, Romania). KD stands for "Kirov diesel"

7. DT-75 is a caterpillar agricultural tractor for general use. The most mass caterpillar tractor in the USSR (today more than 2.7 million copies). In 2008, the Volgograd Tractor Plant celebrated the 45th anniversary of the start of the DT-75 production. The tractor gained a good reputation due to the successful combination of good performance (simplicity, economy, maintainability) and low cost compared to other tractors of its class ![]()

The use of sledges and icy snow roads allowed the horses to pull much more weight than otherwise they could pull with wheeled trailers on unpaved roads. Lombard sought to replace horses by steam, increasing the amount of work that could be done, and reduce the cost of work. Steam tractors with a steam engine could pull along many sledges filled with logs, reduce the cost of transportation.

In other places there were problems with soft soil. One such area was the half of the San Joaquin and Sacramento delta in the south of Stockton, California. The earth was very rich in nutrients, but very soft - almost too soft for horses and, of course, too soft to support heavy agricultural machinery on wheels. In this area, the producer of agricultural machines, including large combines and steam tractors, lived. He was keenly aware of the need for equipment that could collect the grains grown on the delta.

8. ЛТЗ-120 - wheeled tractor universal-rowed. LTZ - Lipetsk Tractor Works

9. SCTZ 15/30 - a brand of wheeled tractor, manufactured since 1930 by the Stalingrad Tractor Plant and since 1931 by the Kharkov Tractor Plant. 390 thousand tractors were produced. Production collapsed in 1937

Benjamin Holt owned a farm on such soft soils. At that time, steam tractors were widely used in this area for agricultural harvesting. To overcome the problem of weight distribution on soft soils, the iron wheels on tractors were increased horizontally to the ground, which allowed the use of very wide tractors of almost 50 feet.

The wider the wheels, the less maneuverable the tractor became. This became a real chronology of analytically verified plans and programs, patriotic exploits and the spiritually rich life of Belarusian tractor drivers. His first editor was journalist Mikhail Yegorovich Kusov. In the diesel workshop was installed the first line of automatic processing of the cylinder head.

11. T-150 and T-150K brands of universal high-speed tractors produced by the Kharkov Tractor Plant. The T-150 tractor has a crawler drive, and the T-150K has a wheel. Historically, the wheel variant (T-150K) of the tractor was made later and based on the caterpillar, but it was much more widespread

Chudakov - project of a wheeled tractor. The anniversary of the October Revolution, the first starting engine was assembled. In June, the assembly of the first model of a wheeled tractor for factory construction in a test shop was completed. Chief designer of the Minsk Tractor Plant Ivan I. Droong offered to give the new car a beautiful and glorious name Belarus, with which he began his journey through the land.

On the anniversary of the October Revolution, tractors producers presented their homeland - the first Kirovets tractor. This first victory was the beginning of mass production of caterpillar tractors. This year, the Minsk Tractor Plant was launched. The first forest tractors "KT-12" came from the main production line of the plant.

13. Self-made tractor and T-16 (in the background). T-16 was often used in the housing and communal sector

14. DT-54 is a general purpose caterpillar agricultural tractor. The tractor was produced from 1949 to 1963 by the Stalingrad Tractor Plant, from 1949 to 1961 by the Kharkov Tractor Plant, from 1952 to 1979 by the Altai Tractor Plant. Totally 957900 units were built

In October, the first wheeled tractor of the Belarusian MTZ-2 family, 36 horsepower from the main production line, ran. In May, serial production of forest tractors TDT-40 began. In May a hundredth thousand Belarusian tractor ran from the main production line.

The MTZ-50 tractor has successfully passed state tests. In October, a new main production line was put into operation. The Union Association "Tractorexport" was established. After this union began to function, all Soviet wheeled and caterpillar tractors were sold abroad with the symbol of Belarus, which spoke of their global authority and high competitiveness.

15. T-74 - Soviet caterpillar tractors of traction class 3 tons produced by the Kharkov Tractor Plant. It was created by modernization of tractors DT-54, T-75. The tractor is designed for agricultural, transport operations in regions with a moderate climate. Produced from April 1962 to November 24, 1983

The first production line MTZ-50PL passed from the main assembly line - a transitional model of the Belarusian tractor, a continuous transition to the production of new machines. According to the staff of the main design department, the pilot workshop produced the first models of the MTZ-80 tractor with a capacity of 90 horsepower.

Minsker Motorworks, a specialized company for diesel engines, was put into operation. The standard production of tractors Belarus MTZ-52 began. In March, the 400,000th tractor Belarus proceeded from the main production line of the Minsk Tractor Plant.

16. MTZ-50 "Belarus" is a brand of wheeled tractors of general purpose manufactured by the Minsk Tractor Plant from 1962 to 1985

17. Т-4, Т-4А, Т-4АП - brands of caterpillar tractors produced by the Altai Tractor Plant. The T-4 tractor was manufactured from 1964 to 1970

A research center was built at the Minsk Tractor Plant. For achievements in the implementation of the 7-year plan, the development of new machine designs and the use of new technologies, the tractor plant received the Order of Lenin. For the great achievements made by employees in the production of tractors and the development of high-performance agricultural machines, the Minsk Tractor Plant of the Lenin Order was awarded the Order of the October Revolution.

The first test tractors of the MTZ-80 family of products were assembled, more powerful than the MTZ-50 and 30% more powerful. Belarusian tractor MTZ-80 successfully passed exams at the University of Lincoln. Another major victory of Belarusian tractor drivers: a two-million-dollar tractor of the Belarusian product family ran from the main production line of the Minsk Tractor Plant.

18. Fordzon Putilovets - wheeled tractor, produced at the factory "Red Putilovets" in Leningrad in 1924 under the license of the company Ford. It was a copy of the American tractor Fordson-F