Year of manufacture of tractor t 40

The rear and front wheels of the T-40 tractor belong to its running gear. Wheels can be installed in different positions both in width and height, thus changing the track and the agrotechnical clearance.

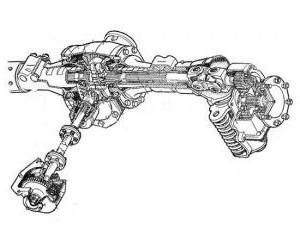

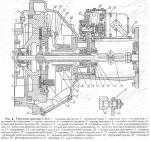

The front axle is used as a support for the front of the tractor, as well as for changing the direction of the front wheels by steering. The axis consists of a beam attached to the front beam bracket. The brackets of the front wheels are attached to both sides of the beam. The wheel is mounted on the shaft flange of the axle journal. On this shaft from above there is a rotary arm, which, under the action of the steering rods, turns the wheels.

Front axle: 1 - cork; 2 - cover; 3 - a nut of a pin; 4, 6 - tapered bearings; 5 - axle journal; 7 - a nave of a forward wheel; 8, 14-bushings; 9 - ring; 10 - the bearing; 11 - a bracket of a forward wheel; 12 - a spring; 13 - shaft of the axle journal; 15, 25-bolts; 16-oil; 17 - the hinge in gathering; 18 - the rotary lever; 19 - lock nut; 20 - steering draft; 21 - a beam of a forward axis; 22 - a finger of a forward axis; 23 - bipod; 24 - a lining in gathering; 26 - clamps; 27 - a spherical finger; 28 - cover; 29 - loose leaf; 30 - an adjusting stopper; 31 - wire.

Rear wheels T-40 (leading)

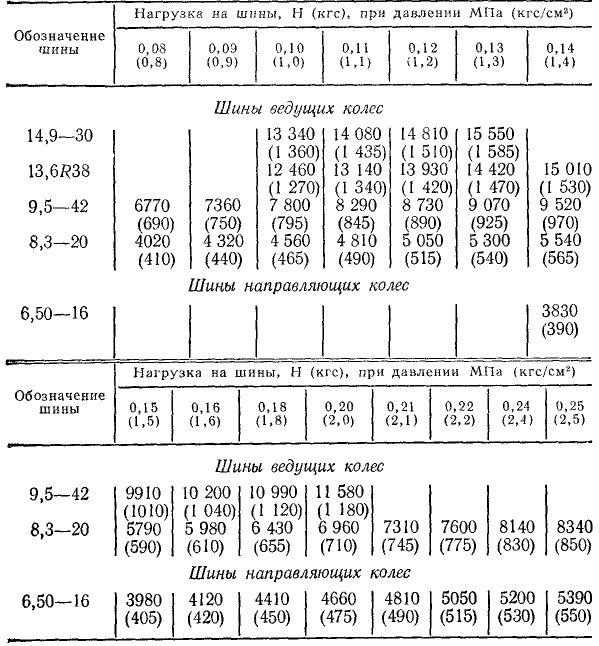

To convert the torque transmitted by the engine, the rear wheels are applied to the forward motion. The wheel assembly includes a pneumatic tire, a disk and a rim. The wheel is screwed to the flange of the semi-axle of the final gear. When performing heavy work on the tractor on its discs, it is recommended to install additional weights to increase its coupling weight. When transporting goods in dry weather, it is recommended to remove loads from the driving wheels. The nominal tire pressure T-40 13,6R38 of the driving wheels should be 0.10-0.14 MPa (1.0-1.4 kgf / cm²), depending on the weight of the attachments and the type of work performed.

The rear wheels of the tractor T-40ANM, 14,9-30 have a different attachment to the disc and a smaller outer diameter. The tire pressure should be in the range of 0,10-0,13 MPa (1,0-1,3 kgf / cm²). The size of the rear wheels is 11.00-38 ".

1 - cargo; 2 - a washer; 3, 4 - nuts; 5 - a bolt; 6 - the insert; 7 - the tire; 8 - a disk with a rim.

Front wheels (guides)

To change the direction of the tractor with the steering mechanism, the front wheel guides are used. As well as the rear wheel, the front wheel consists of tires, a hub with an axle and a rim. The rim, complete with the tire, is mounted on the hub and is fixed with straps. The front wheel rotates on two roller bearings mounted on a trunnion whose flange is bolted to the flange of the shaft of the axle journal.

During the adjustment of the axial clearance of the tapered roller bearings of the front wheels, the axial clearance is considered normal, if there is no appreciable play, and the wheel rotates freely. In order to check the axial clearance, it is necessary to lift the front wheel over the ground surface with a jack and, swaying it in the axial direction, to reveal the size of the gap.

If there is an axial clearance greater than 0.5 mm, the tapered bearings should be adjusted according to the following steps:

1. Drain the oil from the wheel hub;

2. Unscrew the hub cover and remove it;

3. untwist the crown nut and, twisting it, set the wheel so that it rotates freely in the absence of play; without touching the position of the crown nut, clamp it in and replace the hub cover;

4. Fill the hub cavity with the oil to the axis of rotation of the wheel and wrap the plug.

The front wheels of tractors T-40AM and T-40ANM are leading. The wheels are attached to the axle shaft of the final drive of the front drive axle. Since the tractor T-40ANM is used for work on mountain slopes, the lower limit of tire pressure should be 0.18 MPa (1.8 kgf / cm²).

Front wheel: 1 - a disk of a wheel; 2 - wheel rim with brackets; 3 - special washer; 4 - a bolt; 5 - a washer; 6 - a nut; 7 - the tire.

T-40 tractor tires and their operation

To ensure that the tires of the tractor are in good condition, you must perform the following actions:

1. Observe the internal tire pressure;

2. Do not allow significant slippage of the drive wheels while the tractor is running;

3. In case of uneven wear of the tread covers of the drive wheels - rearrange the tires periodically from the furrow wheel to the field wheel and vice versa;

4. Do not allow oil products (fuel, oil, etc.) to get on the tires;

5. Clean tires from foreign objects stuck in the treads;

6. When storing the tractor for conservation, place it on the trestles so that the tires do not touch the ground;

7. Observe the installation and dismantling of tires.

The size of the front tires is 11.2 - 20, and the rear 15.5 - 38.

Mounting the tire onto the rim of the tractor

The tire of tractor Т-40 is mounted on a rim of a wheel in the following sequence:

1. Drive one side of the tire through the rim flange. To do this, put on the first part of the bead, and then using the mounting blades, pull the entire board;

2. Powder the chamber with a thin layer of talc, insert it into the tire and carefully spread it. The chamber's nipple (valve) pass out through the hole in the rim;

3. Drive the second side of the tire over the edge of the rim, by first putting on the side of the bead, and then using the blades, pull the rest of the tire. The tug of the board must end at the nipple of the camera. When installing the tire, carefully follow the correct position of the nipple: its misalignment is unacceptable.

4. inflate the tire to normal pressure and check for air leakage.

When mounting the tires on the drive wheels, pay attention to the direction of rotation of the wheel after the tractor is mounted on the tire with the arrow on the tire.

How to disassemble the tractor wheel

The tire is dismantled as follows:

1. release the air from the chamber;

2. Slide both sides of the tire from the flanges of the rim into its recess from the side opposite to the nipple of the chamber;

3. Insert two mounting blades between the rim on the side of the nipple and the side of the tire at a distance of 10 cm on both sides of it;

4. Pull the rim over the rim first part of the side of the nipple, and then the entire board;

5. Remove the nipple from the hole in the rim, and then completely the camera;

6. Turn the wheel over and slide one side of the tire bead into the rim of the rim, and on the other side, insert the blades and remove the rim from the tire.

At a speed not exceeding 8 km / h, the load on the tires of the driving wheels is allowed to increase to 40%, guiding up to 50%, while increasing the tire pressure by 25%. When working with KUN at a speed of not more than 8 km / h, an increase in the load on the front wheels to 100% is permissible.

Adjustment of the toe of the tractor wheels

The convergence of the front wheels is adjusted by setting the steering wheel to the middle position by changing the length of the steering links as follows.

Agriculture is increasingly gaining popularity in Russia. But not everyone can afford the acquisition of new machinery, for processing fields and harvesting. If the area is small, then a small and versatile transport is best for work, with relatively little cost.

Tractor T-40

T-40 - a tractor, which has become almost a legend. Famous brand, which was produced in the period from 1961 to 1991, located in the city of Lipetsk.

This was mainly used for plowing fields, as well as processing fairly light soils. It is not excluded and hay making. Due to its small size and at the same acceptable power, the tractor was also used for working in the greenhouse, as well as for a variety of cargo transportations.

Design

The T-40 is a tractor with a fully standard semi-frame construction, which consists of a gearbox carrier and a dependent motor. It is located in the front part and is mounted on a small separate frame, which in turn is rigidly fixed to the T- 40. The tractor is renowned for reliable rotation transmitted to wheels with increased diameter. The wheels are attached to the frame with a rigid suspension.

Front, part-time guides, the wheels are much smaller diameter than the rear. The tractor differs from all other modifications by the drive also on the front axle. On the vehicle, designers have the ability to adjust and change the type of work, changing the ground clearance, as well as the wheel rim. To work on very steep slopes to ensure normal stability, it is possible to increase the width of the track. On the tractor T-40 wheels are installed by the "inside out" method.

Engine

T-40 - a tractor, which, regardless of the configuration, set working on a diesel engine brand D-37. The peculiarity of such a power plant is the availability of an air cooling system. The T-40 tractor (photo below) can also be equipped with a D-144 motor with a force of 50 horses. Earlier versions were started with an additional engine of PD-8 brand, running on gasoline. For later versions, an electric starter was installed with the possibility of starting from the cab interior.

Transmission

Due to the specially developed reversible system installed on the T-40, the tractor can operate using the entire set of available speeds for driving both forward and backward. An interesting feature of the design is the location of the bevel gear. It is immediately after the clutch, and as a result of this it was necessary to install the transmission shafts transversely. To carry out work at low speeds, it is possible to install an additional chopper, operating with a hydrostatic or mechanical drive. The T-40 has two power take-off shafts - one rear and the other side. Repair of the tractor T-40 is much easier, just because of the convenient location of all working units.

Job

On this tractor it is possible to work with almost any hinged or trailed equipment, which was developed for both heavier models, such as MTZ, as well as lighter ones like the T-25. This is one of the most important advantages, as there is no need to create a separate equipment for this model or to modify an existing one. The presence of two multi-mode PTO allows a significant increase in the scope of use of this technique.

Engine repair

Sometimes there are situations when during work one of the details stops working normally, this can not be avoided, you can only fix it. The most common problem, which "suffers" tractor T-40 (photo it is given in the article) and its engine - sometimes the engine does not start. The main reason for this is the appearance of clogs in the inner part of the fuel line. To fix this is quite simple - you need to rinse all the hoses, then blow them and dry them. Only after that try to start the power plant again. In some cases everything is much simpler - the air got into the pipeline. The solution is to remove the air bubble by completely filling the system. If the filters fail, wash them and replace them with no difficulty due to the convenient arrangement of the working elements on the frame.

Sometimes the motor can not work at full strength or with small interruptions. In this case, there can be several reasons: air in the power system (this can be solved by purging and cleaning); Also, the cause of unstable operation may be the hanging of individual elements - the valves in the head of the block, plunger or needle, which is used in the nozzle atomizer. All elements must be removed and cleaned. If cleaning has not given the desired result, replace it with new ones.

Before starting the repair of the T-40 tractor, it is necessary to check the fuel line for clogging and to diagnose the pump. The condition of the air filter may influence the normal start of the motor. With insufficient air, an enriched mixture is obtained. The result can be unstable operation of the power unit, as well as increased fuel consumption at a relatively low power, uncharacteristic for such an engine.

Front axle

On the T-40, the front axle plays not the least role, especially when working or driving in off-road conditions. In T-40AM it is the leading one, due to which the thrust significantly increases, as well as the level of patency of equipment. Main working elements:

- reducer;

- transfer case;

- differential;

- suspension;

- final transfer.

In the T-40AM the main gear consists of two gears, one of which is the driving gear, and the second one is the driven one.

Differential is necessary in order to be able to rotate the wheels at an angle (during the overcoming of irregularities or during bends), as well as at different speeds.

The dispenser acts as a kind of binder between the wheels, as well as the drive. Final drives are installed to ensure a reduction in the speed of rotation.

It is very important to remember that in the case of installing wheels with a fairly large diameter and with the front axle disconnected, it is possible that the wheels of the wheels are placed behind them.

Tractor T 40 - wheeled vehicles, the release of which began in 1961 and ended in 1995 at a factory in the city of Lipetsk. This machine is designed for plowing, for working with mowing equipment, a snow removal device. Also the technique is used for carrying out transportation operations and other works that constitute a professional agricultural sphere. On this gear, the drive axle is rear, the layout is semi-frame.

Tractor arrangement

The engine is on the half-frame and firmly attached to the gearbox. This car was produced in rear-wheel drive, as well as all-wheel drive (T-40A) configuration. The rear wheels drive a specialized vehicle, have a firmer suspension and a larger diameter, the front wheels have a smaller diameter with a spring suspension. The penetration of the machine is quite high also thanks to the tire pattern, which is equipped with a herringbone protector. On such a vehicle, there is a function that adjusts the track, as well as a function that regulates the ground clearance. Here it is possible to install rear wheels of smaller width. When the work passes on uneven ground, setting the rear wheels "inside out", the track will be enlarged, since the plane at the wheels is asymmetrical. With certain upgrades, the tractor gets the ability to wear doubled wheels.

The construction of the T 40 tractor consists of various mechanisms and systems. So, there is a system called a carrier. There is an engine, which includes: a fuel supply system, a cooling system, as well as a lubricating system. The design of the chassis includes steering, transmission, running system, which includes suspension and wheels. Specialized equipment is also equipped with a control system and a control post. The equipment is represented by both external and internal elements.

Wheeled tractor T 40

The T 40 engine is a four-stroke four-cylinder diesel engine that is cooled by air. The brand of the engine can be either D-37 or D-144. At the same time, the power of the D-37 engines is 37 horsepower, and the D-144 is 50 horsepower. The combustion chamber of the engine is indivisible, and the start-up is made by means of an electric starter.

Overview of the main technical characteristics

Special attention should be paid to the technical characteristics of the tractor T 40. The specialized vehicle has six speed modes: slow mode and a speed level that is responsible for driving backwards, there is a reverse function for all types of speeds. The thrust action changes depending on which gear is engaged. The length of the machine is 3660 millimeters, the width can vary. This depends on which track is exposed: at a minimum - 1625 millimeters, at the maximum - 2100 millimeters. The height also varies depending on the lumen - at a minimum it is 2370 millimeters, with the maximum - 2570 millimeters. The ground clearance under the front axle is 540 millimeters.

The popular tractor T 40

The minimum turning radius is 3.4 meters. The rated power is 39 + 4 kW, and the power parameters in the operational mode are 37 + 4 kW. There is an inertial - oil air purifier. Also, with the clutch lever, there is a link between the roller arrangement, which blocks the unwanted transition from one speed to another. The frame mechanism, which swings in the shift device between the speed modes, acts on the electric type switch, and excludes the starting of the engine with running speed. Straight, gear gears act as the main gear. The gears, spiral and conical, represent the main high-speed transmission of the bridge support in front of the transport, which appears to be the driving one.

There is an independent drive. In the tractor is a separate-aggregate hydraulic system, double-acting hydraulic cylinders. The stroke of the piston is regulated hydromechanically. The complete set also includes a gear pump with a left shaft rotation. The pump feed is 45 liters per minute. There are two filters: mesh - for rough cleaning and a filter for more fine cleaning. On the steering there is a hydromechanical hydraulic booster. The guns are attached at three points. The largest load-carrying capacity is 850 kg.

The clutch of the tractor T 40 is represented by a clutch, which is designed to disconnect the chain, the power is transmitted from the engine to the gearbox, and also for the short-term disconnection of the chain from the engine to the transmission. The purpose of this is to ensure a smooth start. It is responsible for ensuring that the gear changes are carried out without impact. In order for the clutch to work properly, you need to follow some recommendations. When not required, do not turn off the clutch and do not keep it running at idle.

When driving, do not put your foot on the clutch pedal, do not quickly turn off the clutch, while pressing the pedal to failure. Include smoothly, but do not delay the pedal in an intermediate position, in time to regulate the free running of the pedals. To regulate the clutch, a number of actions must be taken. The driven clutch disc gradually wears out, while the ends of the levers are gradually matched to the bearing. If there is no gap, the arms will inevitably touch the bearing cage, which can ultimately lead to the final wear of the parts where they touch.

In the future, the approach of the levers to the cage will inevitably lead to the fact that the clutch will begin to slip, the clutch and lining worn out. For a good work machine put a gap of 4 millimeters between bearings that are resistant, and levers that are squeezed. Couplings must be adjusted when the free pedal travel is reduced to 2.5 centimeters. Do this with bolts or rods.

The weight of the tractor T 40 of the standard configuration is 2595 kg. This is a rather small indicator for specialized agricultural equipment. Because the device is often used on different types of soil. The fuel consumption of the T 40 tractor depends on the soil and the category of work performed. The average fuel consumption at an average power and revs is no more than 182 g / elec. The fuel consumption per hour is 7.28 kg / h.

Estimated cost of tractors t 40

The price of the tractor T 40 depends on the year of manufacture and the technical condition. The average price is about 80 000 thousand rubles. The cost of second-hand equipment is usually somewhat less. Due to the high safety factor of the running and power transmission, the T-40 tractor was provided with durability. Nowadays there are a lot of cars that were produced in the 70s and 80s. Now they are used in work, both from farmers and large enterprises. Spare parts continue to be produced in large quantities, due to which the transport is in excellent condition and continues to work even in the conditions of modern competition.

Installation of the pump dispenser on T-40

Maximum pressure, MPa: 20

Nominal pressure, MPa: 16

Working volume cm3: 120

The conversion kit consists of the following parts:

1. Pump dispenser for the tractor T-40 (hydrodrive ХУ-120-10 / 1 with the valve block).

2. Pump NSh 32-10 V3L with flanges and fittings for connecting the HPH (wish).

4. A set of fittings and corners.

5. A set of high-pressure hoses.

6. Two repair kits of TsS-75.

How to install a pump dispenser on a T-40 tractor?

To install the hydrostatic power steering on the T-40 tractor, you do not need a hydraulic cylinder, leave your old power steering and just redo it under the hydrodrive.

What you need to install:

1. We disassemble the T-40 GUR and get the piston out of it. The piston we need to modernize a bit.

Turn out two stubs, set and bake, but do not heat the metal when welding (can pull the plunger). For compaction use two repair kits with tss-75.

Preparing the piston for the T-40 gur

2. Preparing the Gura. On the two side covers we put corner fittings, throw out the valve and the ball (through it will drain from the dispenser).

The pump itself can be bought at the T-40 tractor in two places

1. Near the cabin, but you need long Hoses of high pressure RVD.

2. Between the engine and the Gur.

The pump can be connected to the system via the T-40 flow valve or the best way to put the Twin pump 32-10 V3L (Left rotation), but you need to rework the tank (complete one more hole for the oil supply.

Where to buy tractor t 40

Modifications

Tractors with engines D-37 and D-144 (in some sources D-37E) externally differ in the form of the hood: in the first case - rounded, in the second - "rectangular".

Tractors with D-37 engine

T-40 - basic model - rear-wheel drive, engine D-37

T-40A - all-wheel drive model

T-40AN - all-wheel drive model with reduced height and ground clearance for working on the slopes

T-50A - industrial modification for working with a one-bucket loader

Tractors with engine D-144 (50 hp)

T-40M - rear wheel drive

T-40AM - all-wheel drive model

T-40ANM - all-wheel drive model, reduced ground clearance for work on the slopes

T-40AP - all-wheel drive model, designed to work with utility equipment

Spare parts for T-40.

The first universal tractor T-40 came off the assembly line of the Lipetsk Tractor Plant in 1961. Production of tractors T-40 was completed in 1995. The T-40 tractors were replaced by improved models of tractors T-40 - tractor brand LTZ-55. For 34 years in Russia, a huge number of tractors T-40. Tractors T-40 are used in agriculture for plowing of soils, preseeding processing, processing and harvesting of various crops, but this does not end with the use of the tractor. A large number of special equipment intended for work in industry was produced on the basis of the T-40 tractor: the T-40 tractor are used in road construction, mining, oil and gas. Tractors T-40 were produced with engines of the brand D-37 (37 hp) and D-144 (50 hp). The engine is started by means of an electric starter or a starting gasoline engine PD-8. Constructive mass - 2.37 tons (weight of T-40A - 2.57 tons). The speed of the tractor is 1.6 - 26.7 km / h.

Tractors T-40 have earned a reputation for reliable technology. A reliable engine, transmission, chassis provide the T-40 tractor with high performance indicators - tractors produced in the 70s are still used. Reliable operation of tractors is achieved not only due to the successful construction of the tractor, but due to timely maintenance. Quality maintenance can be achieved if original spare parts for T-40 tractors are used.

For tractors it is possible in firms that carry out direct deliveries of spare parts from manufacturing plants. As a rule, a reliable supplier of spare parts for tractors works in the market of spare parts for more than one year, as the sale of original spare parts is a difficult job that requires a lot of time. Unauthorized manufacturer of original spare parts will agree to work with the company without a solid experience in the market of spare parts for agricultural machinery. Qualified personnel, a modern warehouse, equipped with all necessary and extensive experience in the market of spare parts - is the main thing when choosing a reliable supplier. In the Volga Federal District there are few such firms - one of them is LLC "Traktorzapchast". The company has been supplying spare parts for agricultural machinery for more than ten years. You will be offered for tractors T-40. All spare parts are provided with factory guarantees of the manufacturer. There is a modern warehouse equipped with crane-beams, loading and unloading machinery and equipment. Regular customers are given discounts and the opportunity to purchase spare parts with a deferred payment. And also you can arrange delivery.

Buying a spare part in a small store or with hands on the market, you run the risk of buying an artisan craft. The use of substandard parts leads to serious damage, not only the part itself, but also adjacent parts. Contact the companies involved in the purely supply of spare parts for tractors and then you do not have to spend time on replacing substandard parts.

characteristics of the tractor T-40