Old Soviet tractors. Tractor (history of invention). Stalingrad Tractor Plant

The birth of the first Soviet wheeled tractors. HISTORY OF THE MTZ-82 TRACTOR, YUMZ-6 TRACTOR, T-25 TRACTOR, LTZ-55 TRACTOR, VTZ-2027 TRACTOR

HISTORY OF TRACTORS

The birth of the first Soviet wheeled tractors occurred in the early 20s of the 20th century. At that time, a number of enterprises were making attempts to master the production of tractors of various designs. At most of them, everything was limited to either the production of single samples or the production of small batches. At the Leningrad plant "Krasny Putilovets" the beginning of mass production of wheeled tractors was laid. Was taken as a sample American tractor Fordson, produced by Ford since 1917. The design of this tractor was originally created with mass production in mind, which ensured its low cost

Tractor plant in Kharkov

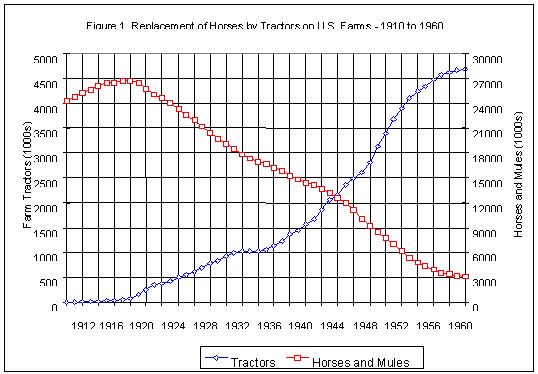

The farm tractor is one of the most important and easily recognizable technological components of modern agriculture in the United States. Its development in the first half of the twentieth century fundamentally changed the nature of farm work, significantly altered the structure of rural America, and freed millions of workers to be absorbed into the nation's rapidly growing manufacturing and service sectors. The tractor represents an important application of the internal combustion engine, rivaling the car and truck in its economic impact.

.

.

For the first time in the world tractor industry, this model had a frameless frame - the engine crankcase was a supporting structure and was integral with the chassis. The two-ton car was driven by a 4-cylinder carburetor engine with a power of 20 hp, it had 3 forward gears and one reverse, and the maximum speed barely reached 11 km/h. The drive was carried out on the rear wheels, the front wheels were steered. The steel wheel rims had no tires. There was no talk of any comfort for the tractor driver - an open cab, an iron seat, dirt from under the wheels directly fell on the tractor driver, since there were no fenders on the wheels. In 1924, large-scale production of Fordson-Putilovets tractors was launched. The tractor was produced until 1933 - during this time (according to data from various sources) about 36-49 thousand Fordson-Putilov vehicles were manufactured. Of course, the bulk of these tractors were supplied to agriculture, however, in those years, Soviet industry provided an extremely meager set of motorized traction equipment, and therefore Fordson-Putilovets was also used in construction. A jib crane was installed on it to perform loading and unloading operations, and it also served as a tractor for a trailed ripper.

A tractor is basically a machine that provides power to the machine to perform agricultural tasks. Tractors can be used to pull a variety of farm implements for plowing, planting, cultivating, fertilizing, and harvesting, and can also be used to transport materials and personal transportation. In providing motive power, tractors were a substitute for human effort and draft animals, both of which are still widely used in other parts of the world.

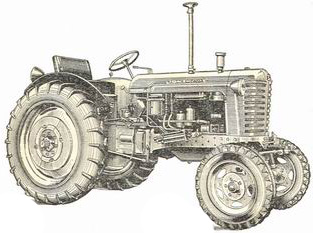

The heart of a farm tractor is a powerful internal combustion engine that drives the wheels to propel it forward. Direct ignition and spark engines are found on tractors, as well as cars and light trucks. Power from the engine can be transmitted to the implement used through a power take-off shaft or belt pulley. The engine also provides energy for electrical system, including ignition and lighting, as well as the latest models, air conditioning, stereo and other creature comforts.

The Fordson-Putilovets was replaced in 1934 by the Universal tractor, which was based on the Farmol tractor of the American company International Harvester. In terms of its main characteristics, this tractor was close to the Fordson-Putilovets: operating weight -2.1t; power of kerosene carburetor engine - 16 hp; maximum speed - 8 km/h. The station wagon was manufactured at the Putilov plant until 1940. Then its production was continued at the Vladimir Tractor Plant - from 1944 to 1955.

The machine is little more than an engine on wheels, with a seat for the operator and a hitch for tensioners centered at the rear. Later models would have had an enclosed cab that allowed the operator to leave the weather, but this model only has simple controls and a metal seat. The drawing shows a wheeled tractor, which includes more than 95% of the machines sold for agricultural use.

History and technological history

Tracked units, also called crawler tractors, were common in California and certainly dominated construction and other non-farm tractor applications. Steam boilers provided driving force for threshing small grains, and a very small number of farmers used newly developed steam traction engines for plowing and other complex tasks. However, draft animals provided most of the power on all types of farms. Along with supplying farms, horses were also relied upon to transport both goods and people.

The most popular wheeled tractor in the pre-war period was SHTZ-15/30. For its production, two tractor factories were built - Stalingrad and Kharkov, with a total capacity of 100 thousand tractors per year. The American International-15/30, one of the best tractors at that time, was chosen as a prototype for this tractor. The design of the foreign prototype was revised to domestic conditions, standards and materials. The 3-ton tractor was equipped with a 31.5 hp kerosene engine.

Horses and mules pulled an impressive variety of farm implements at the turn of the century, including plows, discs, harrows, planters, cultivators, mowers, and reapers. Several important farm tasks were usually performed during this time, including harvesting corn and cotton. Largest quantity energy was needed for plowing, which often forced farmers to keep one or two extra horses above the number needed for the rest of the year. For example, power requirements during plowing were estimated at 60% of the annual total wheat production requirements at that time.

The SHTZ-15/30 had 3 forward gears and one reverse gear, and the highest speed was 7.4 km/h. Externally, the SHTZ-15/30 differed little from the Fordson-Putilovets, and there were slightly more amenities for the tractor driver (fenders appeared on rear wheels). Stalingrad tractor plant commissioned in 1930. The Kharkov Tractor Plant was launched in 1931. At both plants, production of the SKHTZ-15/30 continued until 1937, when this model was replaced by the SKHTZ-NATI tracked tractor. During all this time, more than 390 thousand SKHTZ-15/30 tractors were manufactured at STZ and KhTZ. This tractor used a mounted jib crane, a trailed grader and ripper, and a snow shovel. Since the snow clearing machine was used on city streets, it was equipped with wheels and tires.

Then a new source of energy would be useful to the farmer if it could replace plowing requirements horsepower, if the cost were less than the cost of one or two additional horses. It would be even more valuable if it could economically replace all the functions currently performed by heavy animals, and furthermore if it could facilitate the automation of cotton and corn harvesting operations.

Unfortunately, their size, mechanical complexity, and constant risk of explosion have made these traction motors unsuitable for most North American farms. In all but the driest soils, steam traction engines tended to become mired in mud and refuse to move. Because of these disadvantages, the use of steam tractors slowly increased in the United States during the last two decades of the nineteenth century. However, the growth rate of steam horsepower was much less than the growth of animal horsepower.

The first new post-war model of a wheeled tractor - KhTZ-7 - appeared in 1950. This small-sized tractor was accepted for production simultaneously at the Kharkov Tractor Plant and at the Kharkov Tractor Assembly Plant. The vehicle, with an operating weight of 1.4 tons, was equipped with a 12 hp gasoline engine. The maximum speed reached 12.7 km/h. This tractor differed from pre-war models in more comfortable working conditions for the tractor driver - he was provided with a soft seat with a backrest. The wheels had pneumatic tires. The cabin was open. The tractor used a hydraulic linkage system.

Construction of new production facilities

For the reasons mentioned above, adopting paired power was clearly not a candidate for horse replacement. With the commercialization of the internal combustion engine, a more practical alternative emerged. Farmers bought large numbers of stationary gasoline engines in the first decade of the twentieth century and quickly became familiar with their operation. A wide variety of household chores were simplified through the use of stationary engines, including pumping water, washing clothes, and butter.

Until 1956, about 50 thousand units of HTZ-7 tractors were produced at both plants. Despite the very modest traction characteristics, work was found for the HTZ-7 in construction. At its base, a bulldozer was produced with a blade located at the rear of the tractor. For this reason, the tractor driver's seat was swivel. A loader was also developed on the basis of this tractor. The design of the HTZ-7 tractor was further developed in the DT-14 and DT-20 models, produced by the Kharkov Tractor Plant in 1956-1958. and in 1958-1969. respectively. The DT-14 tractor differed from its predecessor mainly in its single-cylinder water-cooled diesel engine with a power of 14 hp. The DT-20, weighing 1.5 tons, already had a 20-horsepower single-cylinder diesel engine. DT-14 was a transitional version and was not produced for long. But the DT-20 during its production was replicated in an amount of about 250 thousand units. Among the construction and road “professions” of the DT-14 there was also a “backwards” bulldozer and a sweeper.

Kharkov Tractor Plant

The first tractors shared similar features with steam traction engines. These tractors have proven excellent at plowing and are quite capable of driving mowers and reapers. However, the large steel wheels, low clearance and significant weight made them unsuitable for growing growing crops such as corn and cotton. Henry Ford, who tinkered with steam and gasoline tractors before achieving success in automobile manufacturing, introduced a small, inexpensive model he called the Fordon during World War I.

A radical change in the production of wheeled tractors in our country occurred in the early 50s with the development of mass production of tractors in Belarus. From that moment until today, these tractors have become the main “combat” unit in the tractor fleet of our country, including in construction and road organizations.

The designers of the Minsk Tractor Plant began work on the first-born - the universal row-crop tractor MTZ-2 - in 1948 according to the technical specifications of the USSR Ministry of Agriculture, and already in 1949 the first prototype was ready. After comprehensive testing of prototypes, serial production of MTZ-2 tractors began in 1953. The first Belarusian car weighed 3.25 tons and was equipped with a 4-cylinder D-36 diesel engine with a power of 37 hp. and a 5-speed gearbox, the maximum speed reached 13 km/h. MTZ-2 was equipped with pneumatic tires. The cabin was missing.

This model sold well for several years, helped by the war - causing a shortage of horses. The first innovation was the surge in power offered after this device, a metal shaft turned by the rotation of a tractor engine, allowing mounted machines to be driven directly by the tractor engine, as opposed to receiving power from a wheel rotating along the ground.

Power take-off quickly became a standard feature on all tractors, and developers began the process of redesigning their equipment to take advantage of this innovation. Three more improvements were important to complete the technological base of the tractor. This device allowed the tool to be raised before each turn by pulling a lever. Previously, the farmer had to lift the implement manually at every step, which was a labor-intensive task. As with the power takeoff, the power takeoff was quickly adopted by other tractor manufacturers.

From the very beginning of the production of the new tractor, Minsk designers carried out continuous work to improve it. Therefore, in the 50s and early 60s, modernized machines were introduced into production one after another in a continuous sequence. In 1956, the MTZ-5 tractor appeared, which used a 40-horsepower D-40K engine. In 1956-1957 The following model is accepted for production - MTZ-5L/MTZ-5M (the difference between these two options was in the starting system - starting motor and electric starter, respectively). The innovations introduced on this model were more significant: 45-horsepower engine (D-40L/D-40M); 10-speed gearbox; reduced metal consumption (operating weight - 3.07 tons); the maximum speed reached 22 km/h; the resource increased from 2000 to 2500 engine hours. In 1959, the next modernization of the “five” came - the MTZ-5LS/MTZ-5MS received a 48-horsepower engine (D-48L/D-48M, respectively) and a closed cabin with canvas walls and a roof. The resource before overhaul for the MTZ-5LS increased to 4500 engine hours, and for the MTZ-5MS - up to 3000. For a short time, an all-wheel drive model of the tractor was produced - the MTZ-7 series.

Low pressure tires not only reduced field damage, but also allowed for increased forward speed due to reduced friction. Many tractors from that time had a small gas tank for cold starts and a large diesel tank for most operations. At this time, the international harvester launched the "one plow" tractor for the first time and began to sell it. Its introduction offered operators on small farms the opportunity to replace their single horse or mule with a tractor and was responsible for beginning the spread of the tractor in the South.

These small tractors often featured adjustable front wheels and high ground clearance, making them significantly more flexible than larger models. For several years now, manufacturers have been offering their larger models in high-resolution versions. This year the firm agreed to enter into a joint venture with Irish inventor Harry Ferguson.

Due to the unsuitable front drive axle for the tractor, borrowed from the GAZ-63 truck, the MTZ-7 was quickly taken out of production. At the same time, the plant was preparing to release the promising model MTZ-50. In 1958, several prototypes of the new tractor were assembled, based on the test results of which it was recommended for mass production. The MTZ-50 tractor was equipped with a 50-horsepower engine, the operating weight of the machine was reduced by more than 100 kg. The transmission was equipped with a 9-speed gearbox, providing a speed range ranging from 1.65 to 25 km/h. The tractor received a metal cabin, and its design also changed. On the basis of the MTZ-50, a modification of the high cross-country ability MTZ-52 was developed. In order to continuously transition to a new tractor model, the MTZ-50 was gradually introduced into production: in 1961-1962. produced a transitional model MTZ-50PL, which was a chassis of the MTZ-50 tractor with a D48PL engine boosted to 50 hp. The plant began production of MTZ-50 tractors with the D-50 engine in the fourth quarter of 1962. Production of the all-wheel drive version - MTZ-52 - began in 1965. In 1969, the MTZ-50/MTZ-52 tractors were restyled - the rounded front lining was replaced with the then fashionable angular one.

Ferguson worked for nearly 20 years to perfect the “three-point hitch,” a device that produced superior plowing by continuously leveling the implement as it passed over uneven terrain. By the last date, the process of technological diffusion was essentially completed. Except in the Deep South, the year-over-year increase in the percentage of farms with tractors has plateaued.

Development of appropriate equipment

Tractor general purpose has proven to be an excellent replacement for the horse in plowing, soil preparation, seeding and cultivating tasks for a wide variety of field crops. In addition, the tractor was fully capable of providing electricity for cutting hay and harvesting wheat and other small grains. In its latter application, it facilitated the practice known as "pooling", the simultaneous obtaining and threshing of wheat. However, a large group of horses needed to drag the heavy, complex machine across the fields. Ultimately, a self-propelled combine was produced with a tractor engine and cab included in the combines.

The production of tractors in Belarus was carried out simultaneously at two factories - Minsk Tractor Plant and Yuzhny Machine-Building Plant - starting in 1953. Production at YuMZ increased year by year, and by 1961, annual production exceeded 35 thousand tractors. In 1959, the 100,000th tractor rolled off the YuMZ assembly line. Production volumes at MTZ were even more impressive: in 1961, the 200,000th tractor was assembled, and 2 years later, the 300,000th. It should be noted that, at the time when the Minsk Tractor Plant began production of the MTZ-50/MTZ-52 tractors, the Southern Machine-Building Plant continued to produce the MTZ-5LS model until 1970.

Before the development and adoption of the corn picker, corn was often cut with a binder and then hand-shelled. One of the most important applications of stationary gas engines in the early 20th century was corn shelling. The harvester combined cutting and shelling operations and distributed the stems back into the field, eliminating an extra step.

Mechanical cotton pickers fundamentally changed not only the harvesting of cotton, but the very nature of cotton growing in the United States. The mechanical picker, even after extensive development, produced higher yield losses than hand picking in the hot, humid areas where most cotton was grown—Mississippi, Alabama, and eastern Texas. However, in the dry areas of West Texas, the harvester was very efficient, both in terms of labor effort and crop yield.

With the advent of the first tractors in Belarus, factories producing construction and road equipment began producing various special vehicles based on them. Moreover, from year to year, from model to model, the range of construction and road machines became wider and wider. Thus, on the basis of MTZ-2, the first hydraulic excavator in the USSR with a rigid boom suspension was created. Bulldozers, trench excavators, drilling machines, levelers, pickaxers, snow plows, and sweepers were also produced on its chassis. Tractors of the MTZ-5 family were supplemented with new types of equipment: drilling and crane, snow clearing - milling and rotary and plow-brush, loading. This entire train of equipment was transferred to the next model MTZ-50/MTZ-52. However, the most common type of equipment on tractors in Belarus was excavator equipment. Single-bucket excavators, additionally equipped with a bulldozer blade, were produced by several factories at once. Moreover, in Soviet era Tractors from the Southern Machine-Building Plant were mainly used as base tractors for this purpose.

As with the combine, self-propelled corn and cotton pickers were soon developed, combining a power train and a tractor cab into the implement apparatus. For this reason, pickers and combines are often treated as separate machines, and their development and distribution are not taken into account when discussing the impact of the tractor. It should be noted, however, that none of these devices could be effectively powered by horses or steam; To develop them, a gasoline tractor was needed.

The recent history of tractor development is less dramatic than the first 50 years. Since then, approaching market saturation has led to a steady decline in production and sales. As you might expect, manufacturers responded by developing ever larger tractors to supply farms that were growing in size. Interestingly, this desire for size left the small end of the market open to foreign competition and, as with the US auto industry, imports came to dominate the small tractor market.

In the period of the 50-60s, one cannot fail to mention the new generation of Vladimir tractors. In 1956, instead of the Universal tractor, the DT-24 model was put on the conveyor. This machine was equipped with a 2-cylinder liquid-cooled diesel engine with a power of 24 hp, its weight was 2.59 tons. Maximum speed reached 19 km/h. The DT-24 was not produced at VTZ for long - until 1958, after which another tractor - the T-28 Vladimirets - entered the production line. The T-28 became less metal-intensive (390 kg lighter than the D G-24), and it received a more powerful engine - a 28-horsepower 2-cylinder diesel engine. The tractor speed increased to 25 km/h. But this model was produced very little in Vladimir - until 1961. After that, the plant produced exclusively cotton-growing tractors for more than 10 years. During the entire production period, about 50 thousand DT-24 tractors and 82.5 thousand T-28 tractors were assembled at VTZ. Perhaps, due to the fact that the DT-24 and T-28 were manufactured for a short time, they did not have time to be included in the nomenclature reference books.

In the second half of the 50s, the Kharkov Tractor Assembly Plant (later the Kharkov Self-Propelled Tractor Chassis Plant, KhZTSSh) began producing small-sized tractor chassis with an original layout - the front part of the machine was a tubular frame, behind it was a cabin, the engine was at the rear. The first model - DSSH-14 - was released in 1956. It used a 14-horsepower diesel engine, unified with the DT-14 tractor engine. The operating weight of the tractor was 1.67 tons. The 6-speed gearbox provided a maximum speed of 13.7 km/h. A dump platform could be installed on the tractor. The cabin was open. Two years later, the plant began producing the improved DVSSH-16 tractor. The weight of the tractor was reduced by 200 kg, the speed increased to 17.2 km/h. Further design changes led to the appearance of the T-16 model in 1961. This tractor used a 2-cylinder diesel engine D-16 with a power of 16 hp. The maximum speed reached 19.6 km/h. The platform's carrying capacity was 750 kg. Operating weight decreased to 1.43 tons.

The T-16 and its later versions served as the basis for the creation of various road construction vehicles. On the basis of this tractor, excavators, cranes, derricks, vibratory soil compactors, sidewalk cleaning machines with plow-brush equipment, road marking machines, installations for static soil probing, etc. were produced.

![]()

The beginning of the 60s was marked by the appearance of new generation tractors at three enterprises at once - at the Lipetsk and Kharkov tractor plants, as well as at the Leningrad Kirov plant.

The Lipetsk Tractor Plant, which at that time produced tracked tractors, was faced with the task of mastering the production of wheeled vehicles. In 1958, the designers created the T-25 tractor, which, after fine-tuning, received the designation T-30 and was accepted for use in 1960. serial production. On the basis of this tractor, a more powerful model T-35 was created. However, the T-40 tractor went into mass production in 1961, representing a further development of the design of the T-30 and T-35 tractors. Along with Belarus tractors, the Lipetsk T-40 has become another bestseller in domestic tractor manufacturing: over the entire production period - from 1961 to 1995 - about 1.2 million T-40 tractors of various modifications were manufactured. The T-40 tractor with an operating weight of 2.75 tons was equipped with a 4-cylinder air-cooled diesel engine D-37M, which developed a power of 40 hp. The 7-speed gearbox allowed operation in the speed range from 1.62 to 26.7 km/h. The T-40 had a closed metal cabin. Since 1965, the plant has produced an all-wheel drive version of the T-40A tractor.

The T-40A tractor has found greatest use among road workers. On its basis, a universal cleaning machine KO-705 was developed, intended for year-round maintenance of road surfaces. The machine had a wide range of attachments - plow-brush, milling-rotor, ice-breaking, watering-washing, sand-spreading. In addition, bulldozers, grab loaders and other machines were produced on the T-40/T-40A.

In the 60s, KhTZ created a fundamentally new model of the T-125 tractor. Its design was unconventional for that time - wheels of the same size, an articulated frame, which made it possible to do without a traditional steering mechanism (the wheels turned by “folding” the frame). The T-125 used a 130-horsepower AM-03 diesel engine, the transmission had 16 forward gears and 4 reverse gears, the front axle drive was switchable. Between 1962 and 1967 the tractor was produced in small batches. About 200 copies of the T-125 that were released underwent extensive testing under real operating conditions. The experience gained during the production and operation of these tractors made it possible to subsequently establish mass production of the T-150K tractor. Despite the small circulation, the T-125 was used as a road construction vehicle. For the needs of the Soviet army, an engineering vehicle was created at its base, equipped with a chain excavator and a bulldozer blade. The tractor was used as a tractor for heavy trailers used for transporting construction equipment.

In parallel with KhTZ, work on an energy-rich all-wheel drive tractor with an articulated frame was carried out at the Leningrad Kirov Plant. In 1961 in as soon as possible The designers developed the most powerful wheeled tractor in the USSR at that time, the K-700 Kirovets. And already in 1962, the plant produced the first batch of tractors. The K-700 was equipped with an 8-cylinder V-shaped engine YaMZ-238NB with a turbocharged power of 200 hp, the operating weight was 12 tons. The manual transmission provided 16 forward gears and 8 reverse gears. The maximum speed of the tractor reached 30.8 km/h when moving forward and 27.8 km/h when moving backward. The tractor was equipped with a spacious all-metal cabin with an effective heating and ventilation system. In 1964, 1,200 tractors were manufactured; by 1971, annual production exceeded the 11,000 mark. In total, until 1975, when the first Kirovets model was discontinued, 105 thousand tractors rolled off the plant’s assembly line.

In 1966, KhTZ, along with work on a promising tractor with an articulated frame, prepared for production the small-sized tractor T-25, replacing the previous model DT-20. The new product was distinguished by: a 2-cylinder air-cooled diesel engine with a power of 20 hp, an increased number of gears in the transmission (8 forward and 6 reverse instead of the previous 6 and 5, respectively), thus the speed range expanded from 5-17.7 km/h to 1.8-21.6 km/h. Because of new system cooling, the front of the tractor received a lining without blinds.

The T-25 was produced in Kharkov until 1972, after which its production was transferred to the Vladimir Tractor Plant.

Another Kharkov plant, a tractor assembly plant, modernized the T-16 tractor in 1967. The improved T-16M model was equipped with a 20-horsepower D-21 engine, the platform's load capacity increased to 900 kg, and the speed increased to 20.6 km/h. The tractor was equipped with an all-metal cabin. Later, a modification of the T-16MG was released with a D-21A1 engine with a power of 25 hp. and hydrostatic steering. The dump platform could transport 1 ton of cargo. The maximum speed of the tractor was 23.1 km/h.

Tractors of the T-16 series turned out to be long-lived - this machine, with minor changes, continues to be produced at the present time.

In the first half of the 70s, Soviet industry mastered a number of new tractor models.

In 1971, the Southern Machine-Building Plant produced its first own model of the YuMZ-6L/YuMZ-6M Belarus tractor (the difference was in the starting system - a starting motor and an electric starter, respectively). The tractor was equipped with a 4-cylinder diesel engine D-65N/D-65M with a power of 60 hp. and a 10-speed gearbox. The new engine was more economical compared to the previous D-40L/D-40M - specific fuel consumption decreased from 200 to 185 g/e.h.p.h. The weight of the vehicle was 3.09 tons, the speed range was 2.1-24.5 km/h.

Like all previous models of tractors produced by the Southern Machine-Building Plant, YuMZ-6 was used mainly with excavator equipment.

For the Kharkov Tractor Plant, 1972 was a significant year - serial production of the high-speed, energy-rich tractor T-150K, which was a further development of the T-125 design, began. The new model used a 165-horsepower SMD-62 diesel engine. On the basis of the T-150K, an industrial modification was produced - the T-158. Its operating weight was 100 kg higher than this parameter for the base model and amounted to 7.5 tons. The maximum speed of the T-158 reached 44.8 km/h - almost 15 km/h higher than the T-150K. Along with some other legends of the Soviet era, the T-150K is currently being produced.

.

.

Vladimir Tractor Plant, which was inherited from HTZ tractor T-25, in 1973 carried out its modernization. The new vehicle began to be designated T-25A Vladimirets. The engine power increased to 25 hp, the tractor received a closed all-metal cabin, and the design was also modernized. This model has become one of the most popular. Its production lasted until 1999, and modernized versions are still produced today. In total, about 730 thousand of these tractors were manufactured. The T-25A was mainly used for the production of sidewalk cleaning machines. In 1973, serial production was updated at the Lipetsk Tractor Plant - modernized T-40M and T-40AM tractors with a 50-horsepower D-37E engine and a changed appearance began to roll off the assembly line.

A year later, the Minsk Tractor Plant begins the transition to the production of the modernized MTZ-80 tractor, which replaced the MTZ-50 on the assembly line. The main difference from which was the 80-horsepower D-240 engine. In addition, a number of improvements were introduced in the new product, such as: a reduction gearbox, doubling the number of gears; creeper, allowing you to move at a speed of 1.3 km/h; new all-metal cabin, etc. The maximum speed of the tractor has increased to 35 km/h. In 1976, the plant began production of the all-wheel drive model MTZ-82. The bulk of road construction vehicles migrated from MTZ-50/MTZ-52 to the modernized family. However, some new ones have also appeared - for example, hydraulic cranes with a telescopic boom.

The second half of the 70s and 80s are characterized as a period of ongoing modernization of previously produced models.

So, in 1975, at the Kirov plant, instead of the K-700 tractor, the production of two updated models began - K-700A and K-701, differing in engines (YaMZ-238NB with a power of 220 hp and YaMZ-240BM with a power of 300 hp . respectively). The design of the front part of the tractors has changed somewhat. Based on the K-700A and K-701, it has expanded significantly - front-end loaders, bulldozers, rollers, auger-rotary, milling-rotor and plow snow blowers, mounted and trailed cranes, trailed graders and grader-elevators, whipping trucks, etc.

In 1978, the Southern Machine-Building Plant began production of modernized YuMZ-6AL/YUMZ-6AM tractors. Due to the increased by 400 kg operating weight Larger tires began to be installed on tractors. The tractor has changed a little in appearance. During this period, the annual production at YuMZ exceeded 58 thousand tractors.

In 1980, the Minsk Tractor Plant restyled the MTZ-80/MTZ-82 tractors - they began to be equipped with a more spacious and comfortable cabin with a large glass area. Tractors are still produced in this form with minor changes. But at YuMZ a new cabin of a similar type arrived a little later - in 1984. The modernized tractors received the designation YuMZ-6KL/YuMZ-6KM. In 1984, the production of tractors at the Southern Machine-Building Plant amounted to more than 60 thousand.

The year 1984 was also significant for the Vladimir Tractor Plant - the T-30 tractor with a 30-horsepower engine was developed. Since 1989, on the basis of this model, VTZ began to produce the T-30A80 all-wheel drive tractor with a 38 hp engine. Both of these cars are produced before today.

Towards the end Soviet history- in 1988 - the K-701M tractor, equipped with a YaMZ-8423 engine with a power of 350 hp, was introduced into production at the Kirov plant. Along with the new engine, the tractor acquired a modern appearance. Very few Kirov cars with the letter “M” were produced - only 371 copies were assembled before 2000. It should be noted that its less powerful brothers, K-700A and K-701, produced in parallel with the K-701 M, were replicated on an incomparably larger scale. By the end of the 80s, the annual production at the Kirov plant reached 25 thousand tractors. After 1991, the countdown to a new era of tractor construction began. Many tractor factories, previously part of a single ministry, found themselves on opposite sides of state borders. There was a denationalization of enterprises - most of them passed into private hands. Let us hope that the new history of tractor manufacturing in the post-Soviet space will receive its worthy continuation.

The very first tractor in the world, at least its semblance, appeared in the 19th century and worked, of course, on a steam engine. For example, the English scientist and inventor William Howard used a locomobile to plow agricultural land in 1850. By the end of the 19th century, about two thousand such units were working on the lands of Great Britain. Engineer John Frohlich, originally from Iowa (Clayton County, USA), in 1982 designed and patented the first tractor whose engine ran on petroleum products.

First tractor in the world, tracked and powered by a steam engine, was invented by the Englishman John Gitcot, who was also the inventor of the industrial loom. In 1832, he patented his invention, and in 1837 a working copy of the tractor appeared, intended for plowing and draining swampy areas. American W. P. Miller in 1858 invented and designed a caterpillar tractor, which took part in the agricultural exhibition in Marysville, California, for which he received a prize and recognition for his incredible invention. Unfortunately, the inventions of Miller and Gitkot were not further developed. In 1901, inventor Alvin Orlando Lombard built the first recognized practical crawler tractor, the Lombard Steam Log Hauler.

IN Russian Empire Peasant Dmitry Zagryazhsky was the first to announce a self-propelled carriage with movable tracks, i.e. on caterpillar tracks, in 1837. He described his self-propelled tractor as follows: “Near each ordinary wheel on which the carriage rolls, there is an iron chain, tensioned by hexagonal wheels located in front of the ordinary one. The sides of the hexagonal wheels are equal to the chain links; These chains replace to some extent the railway, always providing the wheel with a smooth and hard surface.”

The very first Russian tracked tractor with a steam engine was designed by the peasant Fedor Abramovich Blinov from the village of Nikolskoye, Volsky district, Saratov province. In 1879, he received a patent for “a carriage with endless rails for the carriage of goods on highways and country roads.” The first working prototype of the tractor appeared in 1888. A ready-made steam plant of the required dimensions did not exist at that time, and Fyodor Abramovich independently made it from the iron of a steamship that burned down near Balakovo. Later, he made a second copy of a steam plant, which produced about 40 revolutions per minute and a power of 10-12 hp. The speed of the tractor did not exceed the speed of the bulls - three miles per hour. The principle of operation of the tractor was that it used two steam units - one for each caterpillar. Blinov demonstrated his tractor at the Nizhny Novgorod Fair (1897) and in Saratov (1889), but the tractor never aroused interest among industrialists and did not receive further development.

In 1896, inventors Charles Parr and Charles W. Hart designed a two-cylinder gasoline engine. In 1903, their company produced 15 tractors. The #3 six-ton tractor he built is one of the oldest tractors in the United States and is currently in storage at the Smithsonian National Museum of American History in Washington, DC. The tractor's power plant used a two-cylinder gasoline engine with an ignition system that was disgusting at that time. The engine power at idle was 30 hp, and when performing work - 18 hp.

One of the very first tractors suitable for work was the Ivel tractor, designed by Dan Alborn in 1902. During production, about 500 powerful and lightweight machines were produced.

In 1912, the Holt-Parr company began mass production of tracked tractors. By and large, it was a tractor on a half-track, since metal bands were put on only the rear support wheels. In 1913, at the All-Russian Exhibition in Kyiv, where the Holt tractor was shown, Russian engineers identified its shortcomings, as a result of which the tractor was completely transferred to caterpillar tracks.

In 1917, the Soviet government drew attention to the importance of using agricultural tractors and allocated money for their construction, despite the difficult years. At the direction of V.I. Lenin, in 1918 preparations began for serial production of tractors. In 1919, designer Y.V. Mamin built the Gnome tractor with an oil power unit with a power of 11.8 kW. In 1922, they began production of the Kolomenets-1 tractors, developed by E. D. Lvov. Under the leadership of engineer L.A. Unger, the Zaporozhets tractor was created in 1922-23.

In 1924, the Kharkov Tractor Plant (KhTZ) began mass production of the Kommunar tractor, which was a copy of the German Hanomag WD Z 50 tractor. In addition, in 1924 they began production of the Karlik tractors designed by Y. V. Mamin. The tractor was produced in two versions: the “Karlik-1” tractor – three-wheeled and with one forward gear; "Karlik-2" is four-wheeled, with one forward gear and reverse. The Universal tractor was the first Soviet tractor exported abroad.