Growing fodder grasses: meadow timothy grass

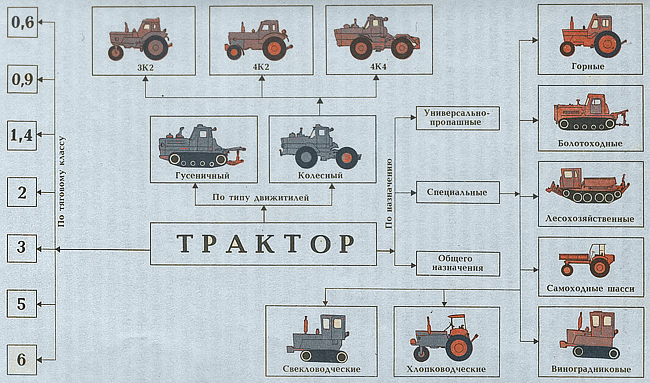

Tractor classification

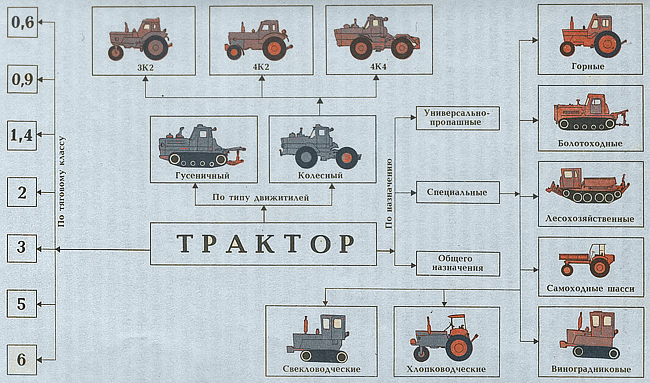

A tractor is a wheeled or tracked self-propelled machine designed to perform various work using trailed, mounted, semi-mounted and stationary machine guns with which it forms a machine-tractor unit (MTA).

Tractors are classified by a number of signs.

By scope- agricultural; industrial; timber industry; forestry.

By purpose and specialization- the following types.

Agricultural tractors.General purpose -energy-intensive work in agricultural production (plowing, cultivation, sowing, etc.), excluding the processing of tilled crops and their harvesting.

Universal -general-purpose work, as well as work on the cultivation and harvesting of tilled crops.

Universal-tilled -sowing, care and cleaning of tilled crops, limited use in primary tillage.

Specialized by crop types and production conditions -cotton-growing, vineyard, beet-raising, rice-growing, tea-growing, tobacco-growing, hop-growing, seed-growing, horticultural, vegetable growing, greenhouse, cattle-breeding, mountain, small-sized and motor-blocks.

Self-propelled chassis -a special type of universal tractor with a front frame for mounting machines and implements.

Industrial tractors.

General purpose- earthmoving in the unit with a bulldozer and ripper.

Swamplands- earthmoving and reclamation work on pounds with low bearing capacity.

Specialized by types of work and production conditions:

loaders - loading, earthmoving and earthmoving;

pipe layers - mechanization of works on installation and laying of trunk pipelines;

underground - work in cramped mining conditions (in mines, on the construction of tunnels);

amphibious and underwater-digging works at a depth of 6 ... 7 m in ports, in the waters of rivers, mining of minerals on the continental shelf of seas and oceans at a depth of up to several tens of meters;

small-sized - low-capacity digging and cleaning in cramped conditions.

Timber industry tractors.Logging -harvesting, collection and transportation of timber in a semi-submerged state.

Swamps -logging on soils with low bearing capacity.

Floating- work on timber rafting in the waters of rivers and the coastal zone.

Forestry tractors. General purpose- forestry work, timber hauling during thinning.

Swamplands- work on soils with low bearing capacity.

By type of suspension system- wheeled and tracked.

Wheels are divided by the "wheel formula", reflecting the total number of wheels, the number of driving wheels and their dimensions. Thus, a “classic” four-wheel tractor with front wheels of a smaller diameter and rear driving wheels of a larger diameter has a wheel formula 4K2. Here the first digit "4" shows the total number of wheels, and the second digit "2" - the number of driving wheels. If, with the same data, the front wheels are leading, but of smaller diameter, then the tractor has the wheel formula 4К4а, where the second digit "4" indicates that the tractor has four driving wheels (all driving wheels), and the letter "a" indicates smaller diameter of the front drive wheels. Tractors with all four driving wheels of the same diameter have the wheel formula 4К46, where the letter “b” indicates the equality of the diameters of the front and rear wheels. There are tractors with a large number of driving wheels, especially among forestry and forestry (6K6, 8K8). A tractor with one or two contiguous front steering wheels has a wheel formula ZK2.

In addition, tractors are semi-tracked and wheel-tracked. In the first case, the tractor has two thrusters (wheel-driven front and tracked rear-wheel drive), and in the second, they are both leading, but only one of the thrusters is used, depending on the working conditions.

By layout typetractors are subdivided into tractors of traditional (classical) and non-traditional layout.

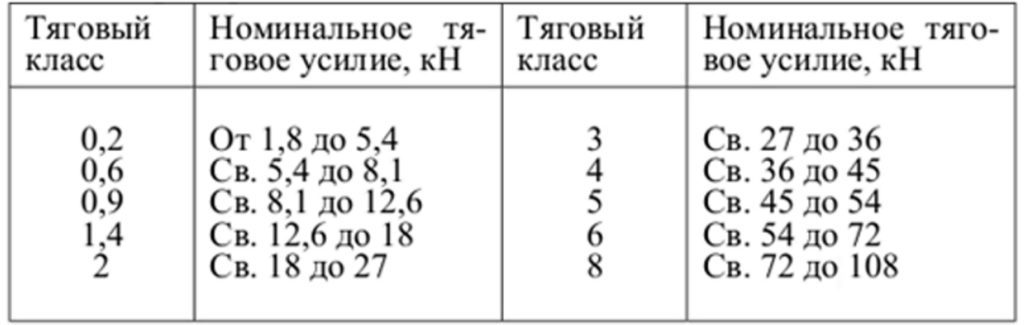

By nominal pulling forceagricultural and forestry tractors are divided into ten traction classes, and industrial and forestry tractors - into eight (Tables 1.1 and 1.2).

Traction classes of agricultural and forestry tractor tractors

Nominal | Rated load |

||

govna effort, kN | new effort, kN |

||

1.8 to 5.4 | From 27 to 36 |

||

From 5.4 to 8.1 | |||

From 8.1 to 12.6 | |||

St 12.6 to 18 | |||

From 18 to 27 | St 72 to 108 |

Under the nominal tractive effort of agricultural and forestry tractors, the force they develop on the average density stubble and at normal soil moisture (from 8 to 18%) is taken in the zone of maximum traction efficiency at the operating weight stipulated by the technical characteristic (for wheeled tractors with ballast weight) at the limit values of slipping: 18% - for tractors 4K2 and ZK2; 16% - for 4K4; and 5% for tracked tractors.

Traction classes industrial tractors

The nominal tractive effort of an industrial tractor is considered to be the greatest tractive effort that it can implement on dense, dry ground. Since this value is interconnected with the structural weight of the tractor, the traction class of industrial tractors is sometimes determined by its mass.

On the territory of the former USSR, Russia and the CIS countries, tractors are classified depending on their technical characteristics, where the traction class plays an important role. It is about her and will be discussed in this article.

The idea to write an article on this topic arose after a combined table was found in the Soviet Encyclopedia showing traction classes of equipment produced in the Soviet Union. At first glance, the table was not easy to understand, besides the information presented in the table is outdated, and for updating the information described in the article, we had to use a number of modern written sources on this topic and catalogs of modern domestic equipment.

The history of the tractor industry

In the process of development of tractor equipment, not only the energy carriers used in power plants (steam, liquefied gas, oil, kerosene, diesel, gasoline) changed. Power plants themselves improved from massive to ultra compact, from simple to energy efficient.

The history of the domestic tractor industry began in pre-revolutionary times. It continued in the revolutionary. During the high pace of national construction, the development of virgin lands, in difficult war times, the production of both serial equipment and promising prototypes did not stop. To automate agricultural processes, construction and industry tasks, it is necessary to cover not only the whole range of nominal traction class, but also various regional requirements, wheelbase requirements, quality requirements, and the scope of application of the unit.

In this regard, the designers of the past were faced with challenging tasks that are still relevant today. One of the sensible solutions to this problem was unification, the consequence of which was the emergence in the domestic industry of basic models of traction class and its modification for various tasks.

Thus, problems were solved with the provision of a set of spare parts and attachments, ease of mastering equipment by personnel. One of the positive aspects of domestic technology was the documentation, understandable for development.

Definition of nominal traction class

The concept of nominal traction class, calculated in accordance with GOST 27021-86, is an exhaustive, detailed characteristic, showing not only the efficiency of the power unit, but also how effective the design of the machine itself with the available operating mass. It is calculated on the basis of normal conditions (average density stubble, soil moisture - 8-18%), in the zone of maximum efficiency and equal to the maximum force developed by the unit.

The table below shows the correspondence of classes of agricultural machinery calculated according to GOST 27021-86 to the classes used for separation according to the classes of equipment according to the ISO standard (ISO 730 \\ 1-77, 730 \\ 2-79, 730 \\ 3-82).

Traction class in the standard GOST 27021-86 Below 0.6 0.6; 0.9 0.9; 1.4; 2 2; 3; 4 5; 6; 8

The corresponding class in standards ISO 730 \\ 1-77, 730 \\ 2-79, 730 \\ 3-82 1 1 2 3 4

Thus, in the description of foreign equipment, you can see a record of traction class as (5-8), which will actually correspond to the 4th class of traction in the ISO standard for agricultural equipment. An example of such a record in the domestic technology can serve as a tractor with a wheelbase PTZ (K-744R1-P4). It became possible with the use of different engines and extended wheelbase on the third and fourth revision of the device.

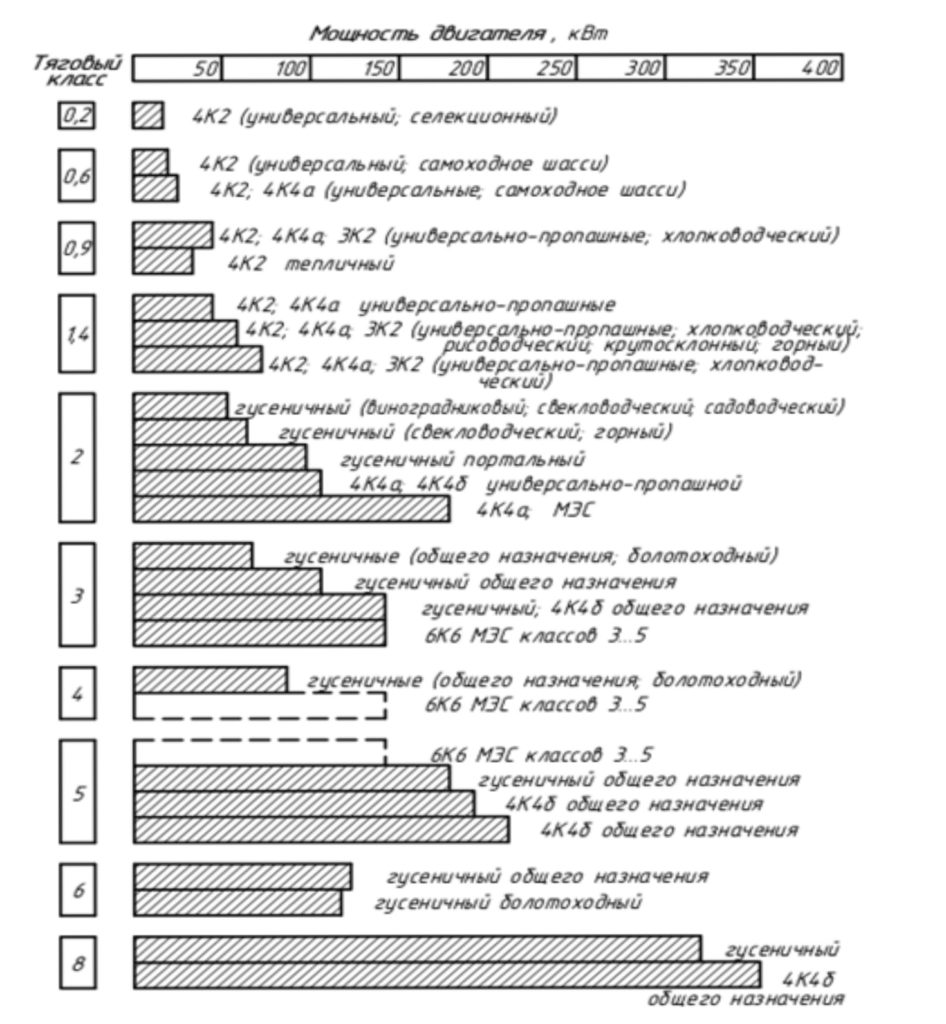

Table and description of individual traction classes of agricultural machinery

To meet the needs of agriculture machinery is produced in ten traction classes. Recently, it has become relevant to use in the description of tractor equipment not only the nominal traction class, but also the engine power. The chart below shows the classification of agricultural aggregates according to the above approach.

The diagram shows the wheelbase parameter:

- 4k2 - means the total presence of 4 wheels, two of which are leading

- 4k4a - means four-wheel drive with a pair of small front wheels and large rear

- 4k4b - the same, but with the same size wheels

Technique with rated 0,2 class

This class includes motorblocks and mini tractors. Mainly used in agriculture in small areas, mainly for work with the aim of breeding new varieties and working out new methods of tillage. Farmers are widely used in various areas, depending on the available attachments. Applicable in livestock farms. They are used by a number of public utilities and at small construction.

HTZ (T-012), Gomselmash (AMZHK-8), Minsk Tractor Works (MTZ-082,), Altai Tractor Works (MT-15), Kurgan Machine-Building Plant (), ChTZ (T-0, 2).

Thrust class 0.6

Tractors belonging to this class are used directly in agriculture and are involved in various technological processes:

- preparing the soil for sowing cultural crops, sowing

- planting vegetables and root crops

- planting ornamental and fruitful trees and shrubs

- care for crops, are involved in the process of caring for shrubs and trees

- harvesting

- preparation of feed for livestock breeders

- transport, utility work, can lead a variety of stationary units

This class includes AGROMASH (30TK), MTZ () HTZ (HTZ-2511, T-30A,) VTZ (VTZ-2032A,)

Technique traction class 0.9

The range of possible jobs and regions in this class is slightly wider. Both fully driven machines appear, as well as machines according to the 4x2 formula, models with low ground clearance for work in mountain areas have been developed.

It becomes advisable to install gearboxes with a wide range of switchable speeds. The main application of this class was:

- plowing light soils

- land preparation for sowing

- interrow hilling

- pest control (crop spraying)

- harvest

- harvesting hay

- transport works

This class includes MTZ (Belarus-422), VTZ (, VTZ-45AT) Agromash (60 TK, 50 TK), TTZ (T-28H4M), LTZ (T-40M, LTZ-60AB-10, LTZ-55A , LTZ-55AN)

1.4 class tractors

From this class it becomes possible to use equipment in difficult road conditions. Representatives of this class are most effective in carrying out the above works of the previous classes and, given their exceptional properties, it became possible to use them for:

- plowing light and medium soils

- cultivations

- harrowing

- for soil fertilizer

This class includes AGROMASH (85TK), MTZ (, MTZ-82, Belarus-923, Belarus 900 series) YuMZ-6AKM, YuMZ-6DM, LTZ-60AB,

Traction class tractors 2

Tracked tractors began to appear from this class. This is connected with the power of the units and with the conditions in which it is necessary to carry out the tasks. This class includes both garden tractors and general and special purpose agricultural tractors, portal tractors. There is an idea of manufacturing integral tractors. By the above types of work added work on:

- vineyard care

- beet work

- gardening

- work in mountain areas

This class includes AGROMASH (160 TK), LTZ (, LTZ-95), HTZ (T-90S), MTZ (, Belarus 1220th, SHU-356) KTZ (T-54, T-70,)

![]()

Tractor 3rd - 5th traction class

In this class, it becomes possible to use the 6k6 wheelbase applicable up to grade 5 inclusive. From the third class, swamp tracked vehicles appeared. Such highly productive machines are also used for general agricultural purposes on large tracts of land of varying degrees of complexity.

3rd class AGROMASH (TG150, 180TK, 90TG), MTZ (Belarus 1500th, MTZ

1523), KhTZ (KhTZ-150K, T-150), CJSC Agrotechmash (ATM 3180), OJSC NPK Uralvagonzavod ()

Of the 4th ATZ (, T-4), KhTZ (KhTZ-201), MTZ (MTZ 2022, MTZ-2103, Belarus 2022)

The 5th PTZ (, K-700), ATZ (T-501), MTZ (Belarus 3023, MTZ-3022).

Tractors of the 6th - 8th traction class

Belong to the most productive agricultural machines. They are used in the most difficult conditions and on the longest sections.

6th PTZ (K-744R2), ChTZ (), AGROMASH (Ruslan)

7th PTZ (K-744R3)

PTZ grade 8 (K-744R4), Rostselmash Combine Plant LLC (Versatile 535), 12x4 wheelbase on July 13, 2010 set a record for handling 417 hectares of land.

Table and description of individual traction classes of industrial equipment

Below is a chart of the classification of industrial, forestry and forestry tractors, taking into account the engine power and the calculated nominal thrust class.

A special feature of the forestry machinery is not the expediency of using for this task machinery below 0.6 class of traction, and for industrial work of tractors below class 2.

Another feature of these units is to consider the use of a fully drive wheelbase with equal wheels, or a track base. “Full-fledged” appears in the 4th traction class, this is primarily due to the severity of the work performed and, not least, to the unevenness of the loads and their various alternating sign values. Industrial and forestry tractors are used for:

Another feature of these units is to consider the use of a fully drive wheelbase with equal wheels, or a track base. “Full-fledged” appears in the 4th traction class, this is primarily due to the severity of the work performed and, not least, to the unevenness of the loads and their various alternating sign values. Industrial and forestry tractors are used for:

- logging

- shipping

- preparation of land freed from the forest for plowing

- soil preparation for construction work

- trenching

- drilling

- laying of water supply systems, communication systems, power supply systems

- development of soil containing minerals

- technological processes in the metallurgical and chemical industries, nuclear power

- works in the municipal utilities, and to eliminate the main problems

Alttrak OJSC - Altai Tractor Plant, Volgograd Tractor Plant OJSC, Promtractor OJSC, ChTZ - Uraltrak LLC can be attributed to domestic manufacturers of this class of equipment.

Prospects and directions of domestic tractor construction

During the Soviet era, great potential was laid for the development of this field. Between the allied states different directions in this industry were divided. After the collapse of the country, many of the manufacturers and consumers of this technology were faced with the choice of further development. Many of the available developments required capital investments, and there were already operating units behind the “frontier”. In connection with the latest global trends and trends in the domestic industry, the shortage of domestic agricultural machines with a wheelbase of traction class of 4-8 was sharply actualized. The development of this very direction for the soonest satisfaction of domestic consumers looks promising in the current conditions.

Tractor classification

TO category:

Tractors-2

Tractor classification

A modern tractor is a self-propelled tractor that performs various tasks both by towing working machines and in stationary conditions. In this case, the working bodies of the towed or stationary machines can be driven from the tractor engine via a pulley or a power take-off shaft.

A self-propelled chassis is a type of tractor with such an arrangement of units and parts, which allows the universal use of the self-propelled chassis for the most rational hanging of various purpose and complexity of working machines.

Schemes of the general device of tractors and self-propelled chassis are shown in Figure 1.

Tractors are classified by purpose, pulling force, type of running gear, type of wreck, type of engine.

By appointment, tractors are divided into agricultural (universal-tilled, general purpose and special) and industrial (general-purpose and special).

Fig. 1. Diagrams of the general device of tractors and self-propelled chassis: a - tracked tractor; b - wheeled tractor; in - self-propelled chassis; g - engine; P - transmission; III - chassis; IV - working equipment; V - auxiliary equipment.

Universal tilled tractors are designed for the most efficient performance of work for the care of tilled crops, but they can also be used to perform labor-intensive agricultural operations (plowing, harvesting grain crops, etc.).

Characteristic features of universal tilled tractors: traction force of 2, 6, 9, 14 and 20 kN, increased distance between the ground and the lowest parts between the wheels or tracks, the so-called ground clearance (600 ... 800 mm), small turning radius ( 3 ... 4 m), variable gauge, the minimum possible width of the wheels or tracks, working speeds of up to 15 km / h, transport 25 ... 35 km / h. Engine power of these tractors ranges from 14 to 73.5 kW.

Tractors of general purpose (arable tractors) are used when performing the most labor-intensive agricultural operation - plowing, but they can also perform operations such as harrowing, sowing, harvesting, etc. These tractors have an estimated pulling force from 20 to 60 kN, operating speeds of 5 ... 11 km / h, and in the future up to 15 km / h, engine power 9 ... 220 kW, ground clearance 250 ... 350 mm.

Special tractors created on the basis of the designs of existing tractors are used to work in specific conditions (swampy or mountainous terrain), as well as to perform special work, such as processing high-stem crops, transporting logs in the conditions of logging, etc.

The design features of special tractors depending on their purpose: marsh - a wide caterpillar to reduce pressure on the bearing surface; mountain - the horizontal position of the body when working across a slope; Cotton - three-wheeled chassis with increased ground clearance and adjustable gauge wheels.

According to the nominal traction force on the lower working gear tractors are divided into the following traction classes: agricultural - 2, 6, 9, 14, 20, 30, 40, 50 and 60 kN; industrial - 100, 150 and 250 kN.

By type of chassis distinguish tracked, wheeled and wheeled tracked tractors.

Tracked tractors have a small specific pressure on the soil (0.035 ... 0.050 MPa), relatively small losses due to skidding, increased grip of the undercarriage with the supporting surface, and improved throughput.

Wheeled tractors are distinguished by relatively low power consumption for self-movement, lower metal consumption, and higher travel speeds when performing transport operations on roads, but they are prone to increased skidding. To improve the traction characteristics of wheeled tractors, sometimes all four wheels of the tractor make driving (wheel formula of such tractors is 4 x 4).

Wheel-tracked tractors have simplified tracked engines, each of which consists of a driving wheel, an anvil roller and a lightweight track that covers them.

Compared to wheeled tractors, these tractors are less prone to slipping due to the reduced specific pressure of the thrusters on the ground. Driving such tractors as well as wheeled, with the help of steering and steering wheels.

According to the type of wreck, tractors are frame, semi-frame, frameless.

Frame tractors as a skeleton have a special frame to which all parts and mechanisms of the tractor are attached. The frame skeleton is characterized by increased rigidity of the mutual arrangement of mechanisms and components, which is especially important for maintaining the alignment of the power transmission shafts.

The frame of the semi-frame tractor is formed from the rear axle housing, to which are attached two longitudinal beams, connected in front of the cross member.

In frameless tractors, the frame is formed by interconnected housings of the power transmission mechanisms and the engine.

Semi-frame and especially frameless tractors have a somewhat lightweight, and therefore less metal-intensive frame. The disadvantages of such a skeleton: reduced rigidity of the mutual arrangement of power transmission units and the difficulty of access to individual components and parts during maintenance and repair.

According to the type of engine, there are tractors with an internal combustion-carburetor or diesel engine and tractors with an electric motor. Predominant distribution on tractors received diesel engines with high efficiency and good technical and operational properties.

Tractor classification

To destination.

Agricultural work is very diverse, so their mechanization requires general-purpose tractors, universal tilled and specialized.

General purpose tractors are used to perform the most energy-intensive agricultural operations, common in the cultivation of most crops.

They have good adhesion to the soil and develop a pulling force of at least 30 kN.

Universally - tilled tractors are used mainly in the cultivation and harvesting of tilled crops. They have less effort than general purpose tractors. For processing different row spacing, the track (i.e. the distance between the right and left wheels) of such tractors can be adjusted.

Specialized tractors are usually created on the basis of existing tractors, adapting them for work on the cultivation of beets, cotton, for work in orchards, vineyards, or under special conditions.

By type of running gear, tractors are divided into tracked and wheeled tractors.

Tracked tractors rely on a large surface, so they have good adhesion to the soil, slightly crush and compact it and work even on moist and loose soils.

Wheel tractors are more versatile than tracked. But their permeability on overwetted and loose soils is worse than that of tracked ones.

According to the type of wreck, the tractors under study are frame and semi-frame.

The first main parts are mounted on the frame of the tractor, consisting of longitudinal beams, fastened with transverse bars.

In the second, the engine is mounted on a short half-frame, which is rigidly attached to the body of the transmission.

According to the nominal traction force tractors are divided in accordance with the traction class.

TO Category: - Tractors-2

In Russia and other CIS countries, tractors are classified according to their traction characteristics. Manufacturers make various models, dividing them according to traction capabilities. Each has its own distinctive characteristics, according to which the equipment is selected for a particular type of work. How different traction class tractors and what this concept means, tell our experts.

Traction classes of agricultural machines is a key characteristic that indicates the maximum tractive power that technology can develop. The traction force will depend not only on the factory characteristics, but also on the type of soil during operation. On clay and marshy soil traction characteristics will be lower than on dry sandy. Therefore, factory specifications for all agricultural tractors are considered under the same operating conditions.

Traction classes of agricultural machines is a key characteristic that indicates the maximum tractive power that technology can develop. The traction force will depend not only on the factory characteristics, but also on the type of soil during operation. On clay and marshy soil traction characteristics will be lower than on dry sandy. Therefore, factory specifications for all agricultural tractors are considered under the same operating conditions.

The classification of tractors by traction is carried out under ground conditions:

The thrust of agricultural machinery is expressed in numbers in a ton of force from the force. At the same time, the tractive force can be expressed in kilonewtons - kN. The ratio of kilonewtons to a ton of force is as follows: 1 tf = 10 kN. So, a 6 ton vehicle is 60 kN. The performance of the same machine on the tracks and wheels during operation may differ, since the first one has a higher patency.

Main characteristics of agricultural machinery

All agricultural machines from the garden motoblock, ending with large industrial models of agricultural machines, are divided into 17 groups according to the strength of the traction. But the popular models of agricultural machines, which are used in private farms, are divided into 8 groups. The first three groups relate to tillers and mini-technology. Recently, manufacturers began to produce more agricultural machines with 7 traction force, previously equipment with this indicator belonged to a large industrial. But due to the development of private farms, the tractor class 7 became demanded by farmers and was transferred to the general purpose.

All agricultural machines from the garden motoblock, ending with large industrial models of agricultural machines, are divided into 17 groups according to the strength of the traction. But the popular models of agricultural machines, which are used in private farms, are divided into 8 groups. The first three groups relate to tillers and mini-technology. Recently, manufacturers began to produce more agricultural machines with 7 traction force, previously equipment with this indicator belonged to a large industrial. But due to the development of private farms, the tractor class 7 became demanded by farmers and was transferred to the general purpose.

The main indicators of all models and traction class tractors table below:

| Thrust force | Power technology in l. with. | Possible tractive effort, kN | Average machine weight, kg | Popular models of technology | |

| On wheels | On tracks | ||||

| 0,1 | - | - | - | Garden motoblock | - |

| 0,2 | 10–14 | 1,8–5,4 | Less than 5 30 | Productive tillers, mini-tractor. | - |

| 0,4 | - | - | - | Jinma (120, 264E), domestic today are not produced. | - |

| 0,6 | 22–25 | 5,4–8,1 | 1 500 | Belarus 300, T30 and T25. | - |

| 0,9 | 40–50 | 8,1–12,6 | 2 600 | T40 | - |

| 1,4 | 55–75 | 12,6-18 | 2 900 | YuMZ 6, Belarus 900, MTZ 80/82. | - |

| 2 | 75-90 | 18–27 | Less than 5,000 | Belarus 1220 | T 70, 54 (special) |

| 3 | 90 | 27–36 | 6 300 | Belarus 1500, T150k | T 150, DT 75. |

| 4 | 130–165 | 36–45 | Less than 7 900 | Belarus 2022 | T 4A, HTZ-201. |

| 5 | From 165 | 45–54 | 7 900 | Belorussian 3023, K 700. | T 501. |

| 6 | 300–400 | 54–63 | Less than 11,600 | John deere 9430 | T 130m |

| 7 | 300–400 | 63–72 | Less than 11,600 | ATM Terrion 7360 | - |

The table shows the main indicators that are taken into account when choosing a model. The more difficult the work is coming and the more land there is, the higher the class of equipment will be needed.

Types of agricultural technology

According to their technical characteristics, force of thrust and power, all agricultural machinery is divided into groups:

- 0.2; 0.4 - mini-tractor. Small, low-power, suitable for work on a private courtyard, used with attachments and trailed equipment. Are applied in agrocomplexes, to garden and road works. Compact and light, easily pass through the narrow streets of cities.

- 0.6; 0.9; 1.4; 2 - universal machines. Used for agricultural and road works. They are used for tilled crops, for planting and harvesting, preparing the soil. This type may include a subgroup of universal tilling machines. Used for the preparation of land for planting, for cultivation.

- Tractor class 3; four; five; 6; 7 - general purpose vehicles. Suitable for the implementation of any energy-intensive road and agricultural work. In agricultural enterprises are used in large agro complexes.

- A separate group with different traction capabilities - specialized agromachines used for specific crops, for example: for harvesting and planting root crops, sunflower, etc.

- Equipment with self-propelled chassis - a narrow ruler, has a low tractive force. For example, the most popular self-propelled tractor T 16.

The most popular types with a different class of thrust will consider in more detail.

Miniature assistants to farmers

Technique 0.2 ton miniature, but in demand in private households. These include powerful tillers and mini-tractor. Suitable for cleaning narrow streets, in a private farm with it you can perform almost any street work. The average price on the market, depending on the manufacturer and power, from 85 00 p.

Technique 0.2 ton miniature, but in demand in private households. These include powerful tillers and mini-tractor. Suitable for cleaning narrow streets, in a private farm with it you can perform almost any street work. The average price on the market, depending on the manufacturer and power, from 85 00 p.

Among the most popular are the following: Belarusian 112; 08K; 132H and MTZ 082, Ural T0.2, KMZ 012. Less adapted, Chinese agricultural machines are also in demand by farmers: Jinma 100 and 200x; Chery PD 15; Dofgan 244; Hintai 220; Photon TE 244.

Cheap and angry

Tractor classes of 0.6 and 0.9 are common among private farms. This is a more powerful agro machine used for various types of agricultural works in areas of 50 acres. Two popular models of class 0.6 are produced at Vladimirsky TZ - T 30 and 25A. Interesting equipment with self-propelled chassis T 16. Of the modern stand out: Belarus 310.3 20, 321 and VTZ 2032. Powerful agricultural machines with good traffic and a large number of attachments and trailing equipment.

Tractor classes of 0.6 and 0.9 are common among private farms. This is a more powerful agro machine used for various types of agricultural works in areas of 50 acres. Two popular models of class 0.6 are produced at Vladimirsky TZ - T 30 and 25A. Interesting equipment with self-propelled chassis T 16. Of the modern stand out: Belarus 310.3 20, 321 and VTZ 2032. Powerful agricultural machines with good traffic and a large number of attachments and trailing equipment.

Traction class 0.9 is represented by modern LTZ 55 (produced from the 90s at the Lipetsk Tractor Plant) and VTZ 45 from Vladimirsky TZ. From proven over the years, stand out T 40 and 40A. The average price on the market from 170 thousand rubles.

Practical and popular

Among the most practical and popular among agrarians are agromachines of the class 1.4 tf. They cope with the work better than mini-types, since power is suitable for performing any kind of work in the fields and on the roads. Tractors of this class are popular in the construction industry, as the price is much lower than powerful production models.

Among the most practical and popular among agrarians are agromachines of the class 1.4 tf. They cope with the work better than mini-types, since power is suitable for performing any kind of work in the fields and on the roads. Tractors of this class are popular in the construction industry, as the price is much lower than powerful production models.

Among the bright representatives of 1.4 ton vehicles are the MTZ 80 and 82 tractors (manufactured by the Minsk Tractor Works), Belarus 900. MTZ 80 has been produced since the late 80s and has established itself only from the positive side. Suitable for working on all types of soil and is used in various weather conditions. Average price from 360 thousand rubles.

Powerful wagons

Interesting for various types of work traction tractor class 2 ton. Until the 80s, class 2 agromachines were produced only on tracks. Among these are known: T 70 and 54B. LTZ 155 is considered the wheel of class 2 of the earliest. It is used for construction, road and agricultural works. High performance with high performance. Among the latter stand out: Belarus 1221 and the improved 1222, John Deere 6020, 6130D made in the USA. The price starts from 270 thousand rubles. Imported are from 450 thousand rubles. But not always imported tractor adapted to our weather conditions.

Appliances for any work

Tractors of a class 3 are suitable for any kinds of agrarian, construction, municipal, road and other types of works. This is a powerful model used in agriculture for large areas. From modern models stands out tractor Agromash, a modified model of the DT 75 on tracks. The wheel equipment is represented by tractors T 150 K and 150 from Kharkov TZ. The average price for class 3 is from 500 thousand rubles. Can afford large farms.

Tractors of a higher traction class are less in demand, as their price is high. Agricultural enterprises prefer models of an average price category with high technical characteristics, as in the video:

What class to choose agricultural equipment depends on the amount of work, the type of soil and material resources of the farmer. The average category of classes is 1.4; 2 and 3 are presented in a wide range of domestic and foreign manufacturers. But we do not recommend saving and purchasing equipment in the secondary market, especially over 10 years. Regardless of the class of traction force, the tractor will break down and work will drag on. And finding spare parts for outdated tractors is difficult. Remember, it is better to overpay than to lose more during seasonal work.